What is the 4 Wings Bearing U-Joint and how does it work?

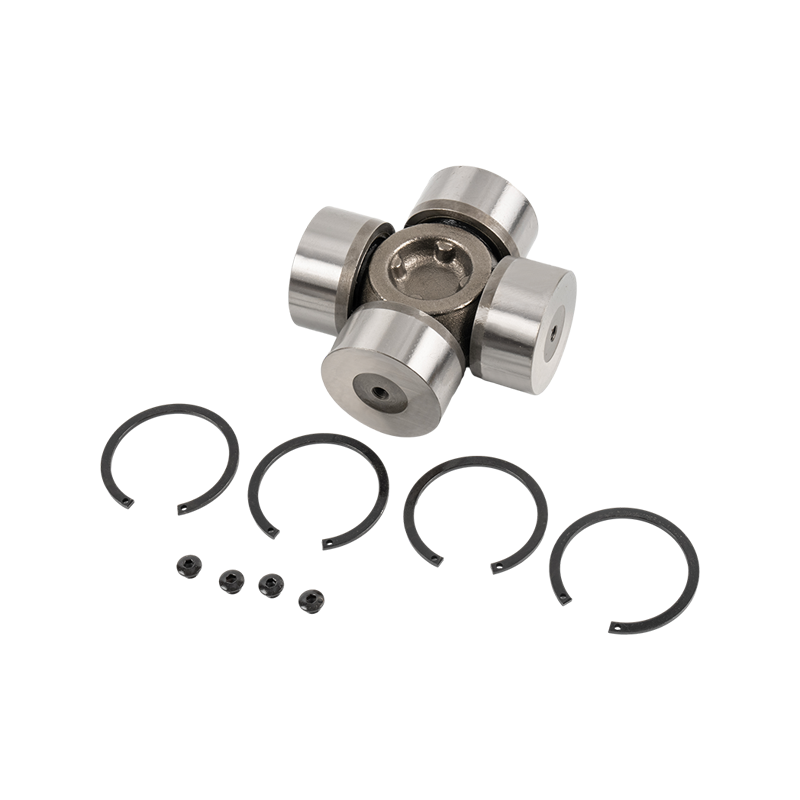

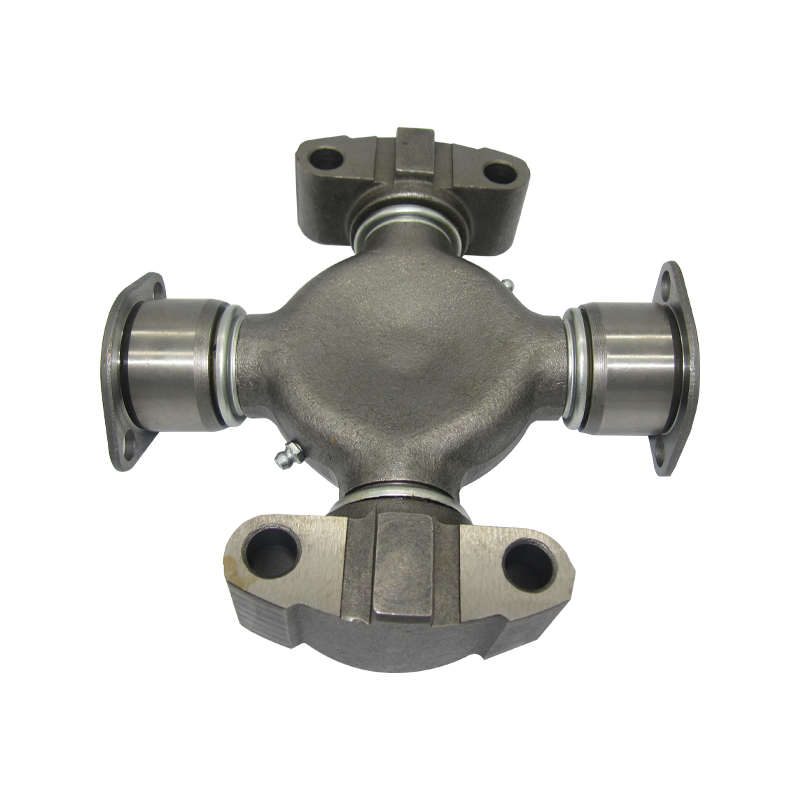

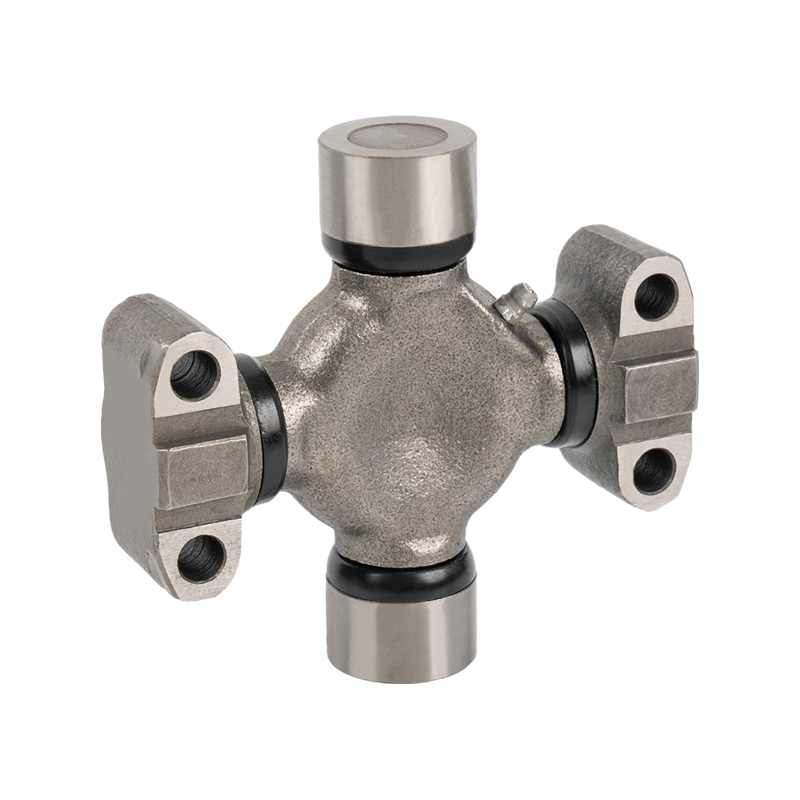

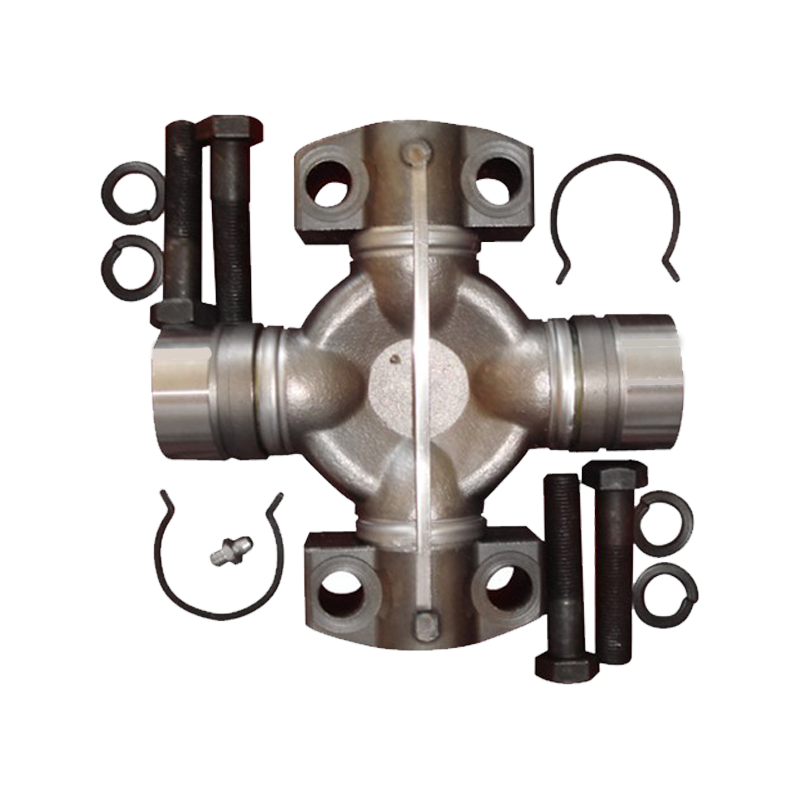

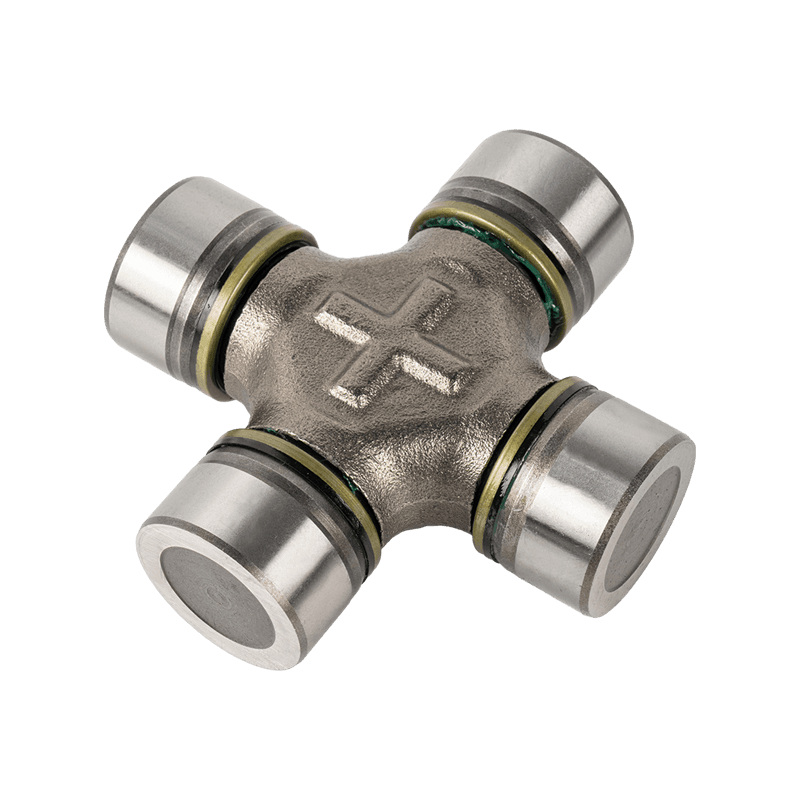

1. Structural composition

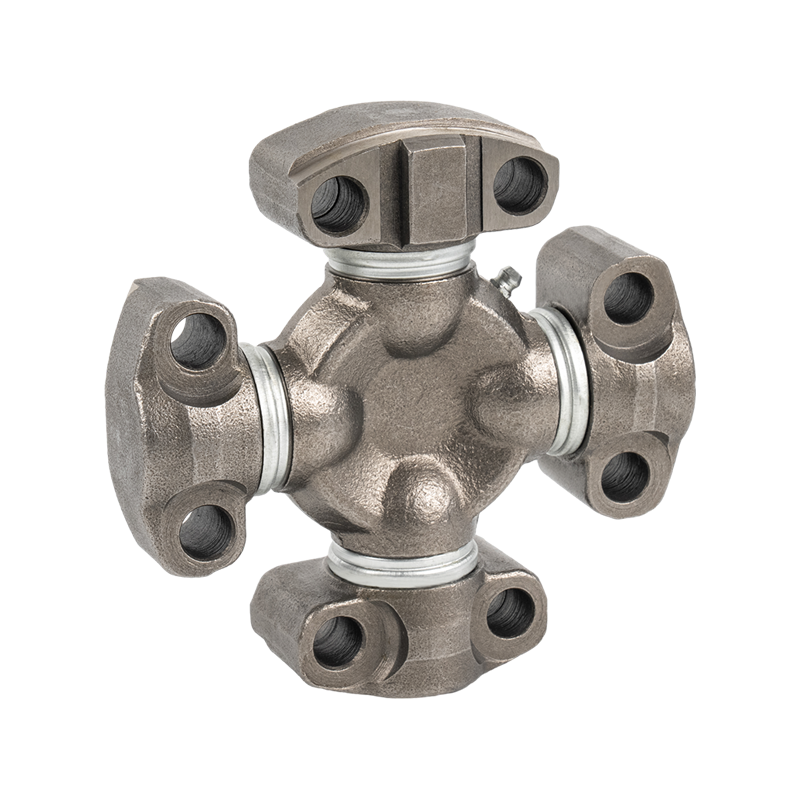

The structural design of 4 Wings Bearing U-Joint is extremely precise, and its core lies in the unique structure of the four-wing bearing. This kind of bearing not only has the load-bearing function of traditional bearings, but also effectively disperses the load through its four wing-like structures, significantly improving the overall load-bearing capacity and durability. The four-wing design makes the bearing more stable when withstanding high torque and complex angle changes, reducing the risk of wear and failure. In addition, as a connecting component, the material and manufacturing process of the universal joint fork are also critical. It must ensure a tight fit with the four-wing bearing to achieve efficient torque transmission.

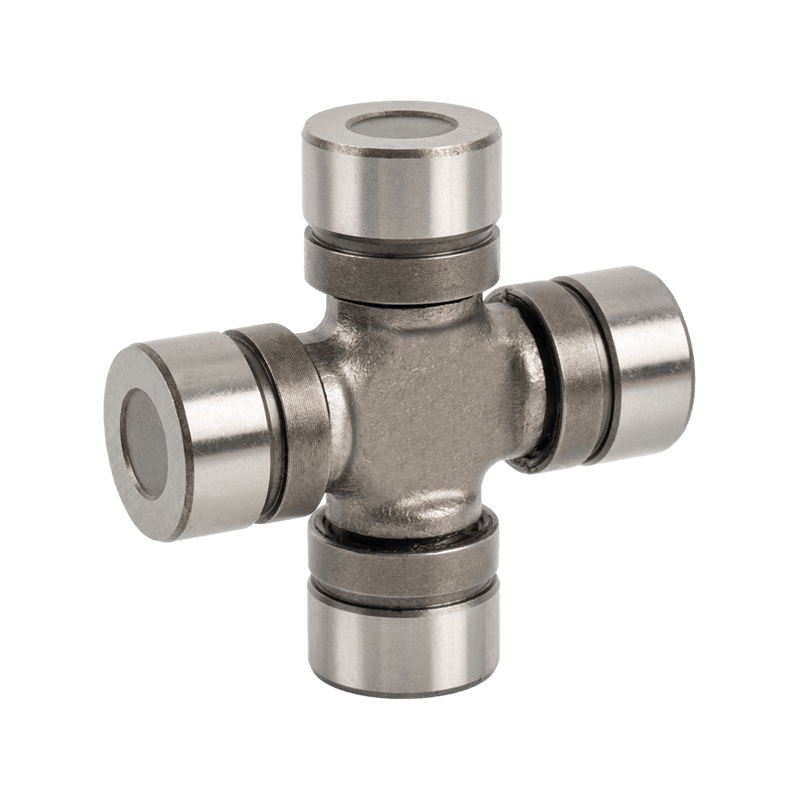

2. Transmit torque

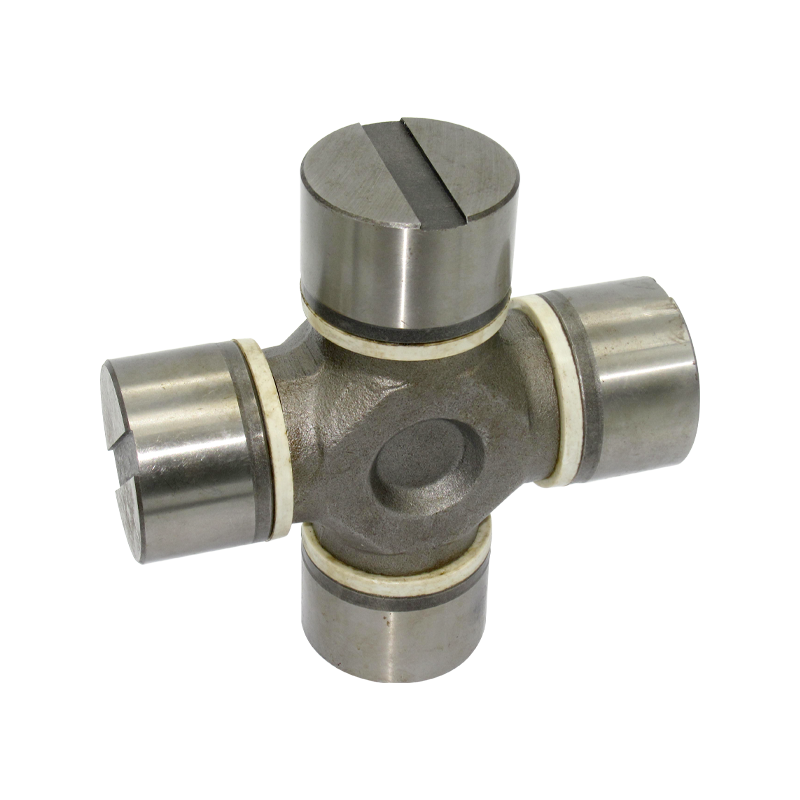

In the 4 Wings Bearing U-Joint, the transmission of torque is a complex and precise process. When there is an angular deviation between the two axes, the flexibility and adaptability of the four-wing bearing allow the universal joint fork to move relative to each other, thereby maintaining continuous transmission of torque. This design allows for a smooth transition of power from one axis to another, ensuring stable power output even under extreme working conditions. In addition, the addition of auxiliary components such as needle roller bearings further improves the efficiency and accuracy of torque transmission and reduces energy loss and vibration.

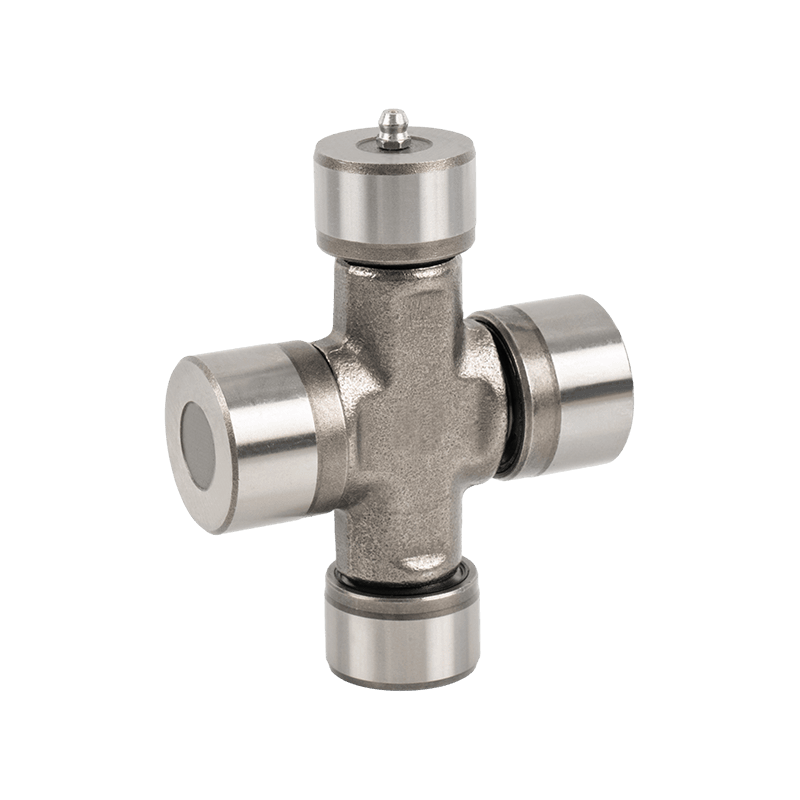

3. Lubrication and sealing

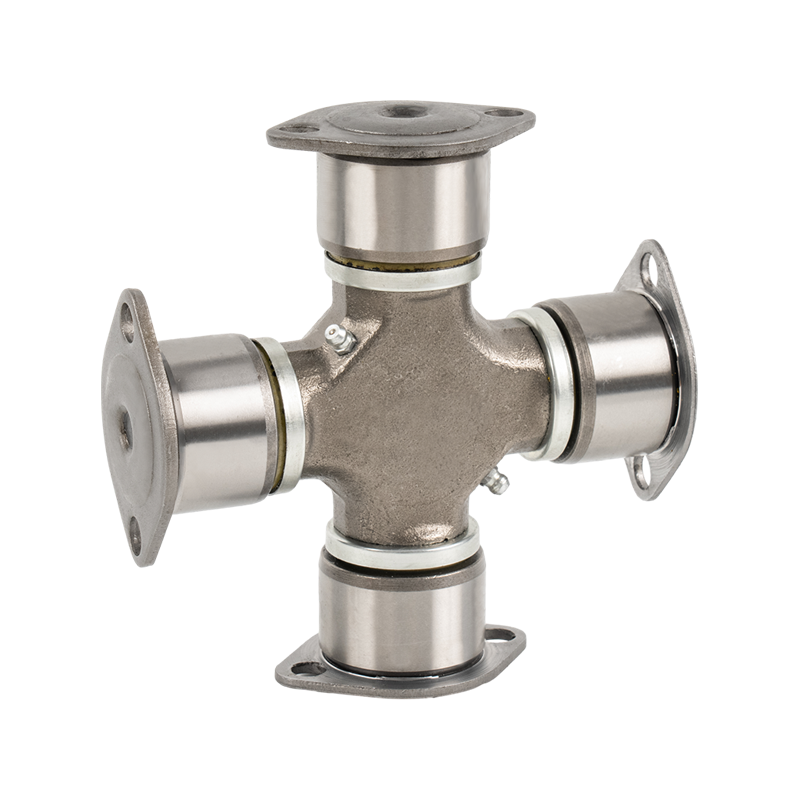

In order to ensure long-term stable operation of the 4 Wings Bearing U-Joint, the lubrication and sealing system are crucial. Inside the universal joint, there are usually special oil passages to deliver grease to the bearings and key friction parts to reduce wear and friction heat. At the same time, the high-quality oil seal design ensures that grease will not leak out and prevents external dirt and moisture from entering the interior, thus keeping the bearings clean and dry. This sealing design not only extends the service life of the bearings, but also improves the reliability and durability of the entire transmission system.

4. Angle adaptability

4 Wings Bearing U-Joint is known for its excellent angular adaptability. It is able to withstand large angular deviations in both horizontal and vertical directions while maintaining continuity and stability of torque transmission. This characteristic makes it particularly suitable for mechanical equipment that needs to frequently change driving directions or faces complex road conditions. For example, in automobile transmission systems, it ensures that power is smoothly transmitted from the transmission to the drive axle and wheels, maintaining stable power output even in sharp turns or bumpy roads.

5. Balance and stability

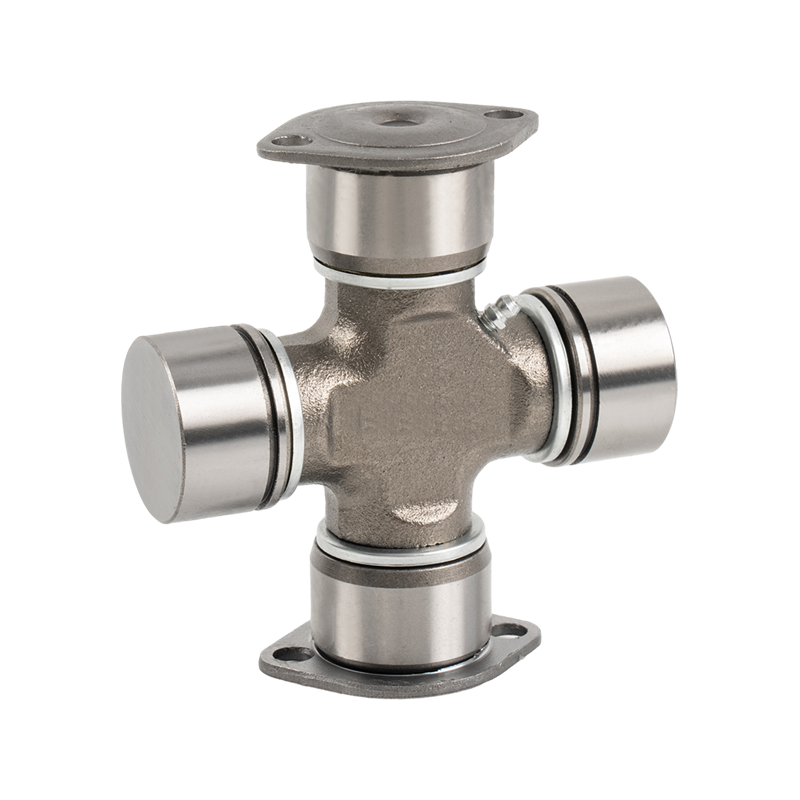

In order to achieve optimal balance and stability, the 4 Wings Bearing U-Joint uses a variety of advanced technologies in the design and manufacturing process. First of all, through accurate calculation and simulation analysis, it is ensured that the geometric size and shape of key components such as bearings and universal joint forks are optimal. Secondly, high-precision processing equipment and processes are used in the manufacturing process to ensure the accuracy and quality of each component. Finally, strict testing and debugging procedures are adopted during the assembly process to ensure the balance and stability of the entire transmission system. The combined effect of these measures enables the 4 Wings Bearing U-Joint to maintain a smooth and reliable state during operation.

English

English 中文简体

中文简体