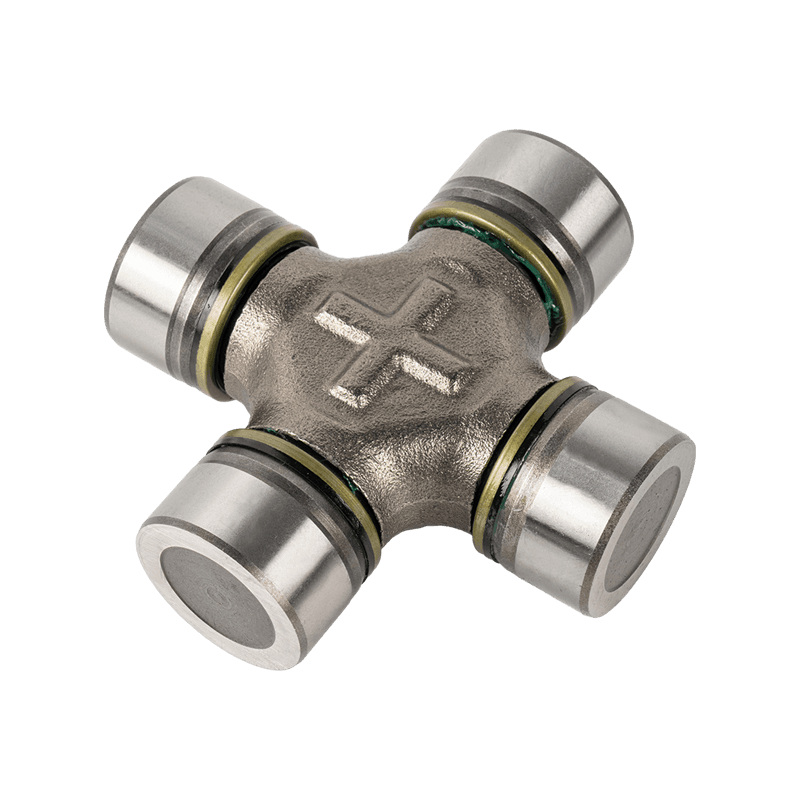

What are the primary applications of industrial equipment cross kits?

Industrial equipment cross kits have various primary applications across different sectors and machinery types. Some common applications include:

Transmission Systems: Industrial equipment cross kits are integral to the transmission systems of vehicles and heavy machinery. These kits facilitate the transfer of rotational power from the engine or motor to the wheels or other driven components. They are designed to connect shafts at different angles, accommodating the inherent misalignment that occurs in complex drivetrain configurations. By allowing for smooth power transmission, cross kits help minimize wear on components such as gears and bearings, thereby extending the lifespan of the drivetrain system. This reliability is crucial in automotive applications where efficiency and durability are paramount, ensuring that vehicles operate smoothly and with minimal energy loss.

Steering Systems: In automotive and agricultural machinery, steering systems rely on cross kits to transmit rotational motion from the steering column to the wheels or steering mechanisms. These kits facilitate the transfer of torque and angular movement, ensuring precise and responsive steering control. Cross kits are designed to maintain shaft alignment and reduce friction, which enhances the safety and maneuverability of vehicles and machinery. Their ability to handle varying loads and operational conditions contributes to stable steering performance, allowing drivers and operators to maintain control even in challenging environments.

Pumps and Compressors: Cross kits play a critical role in pumps and compressors by connecting the motor or engine shaft to the pump or compressor shaft. These kits facilitate the efficient transmission of rotational power, ensuring the proper operation of these essential industrial components. By accommodating axial and angular misalignment, cross kits help maintain the integrity and efficiency of pumps and compressors in diverse applications, including water treatment, oil refineries, and manufacturing processes. Their robust design and ability to withstand high pressures and speeds contribute to the reliability and longevity of pumping and compression systems.

Conveyor Systems: Cross kits are essential components in conveyor systems, where they connect drive shafts and facilitate the movement of materials along conveyor belts. These kits enable the efficient transmission of rotational power across the length of the conveyor, ensuring smooth and continuous operation. By accommodating misalignment and vibration, cross kits help minimize wear on conveyor components and reduce maintenance costs. Their reliability and durability make them ideal for industries ranging from manufacturing and distribution to mining and logistics, where conveyor systems play a critical role in material handling and production processes.

Printing and Packaging Machinery: In printing presses, packaging lines, and other industrial machinery involved in manufacturing and packaging processes, cross kits play a crucial role in synchronizing and transmitting rotational motion. These kits connect shafts within machines, ensuring precise registration and consistent performance during high-speed operations. By maintaining shaft alignment and reducing operational noise, cross kits contribute to the efficiency and reliability of printing and packaging processes. Their robust construction and ability to handle continuous operation make them indispensable in industries requiring precise motion control and high throughput.

English

English 中文简体

中文简体