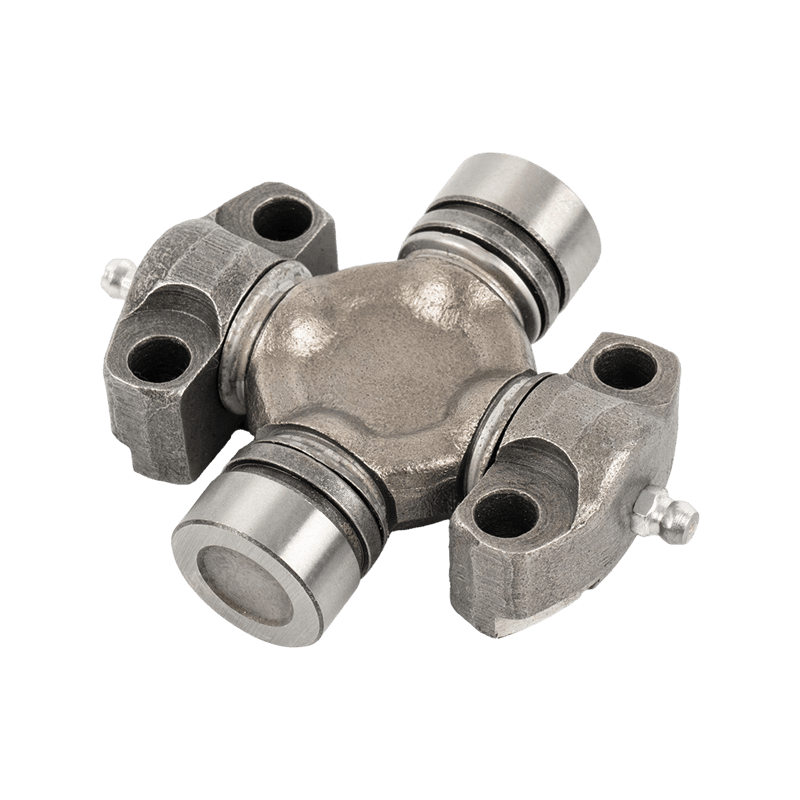

What are the functions and advantages of U-JOINT WITH 4 GROOVED BEARINGS in automobile transmission system?

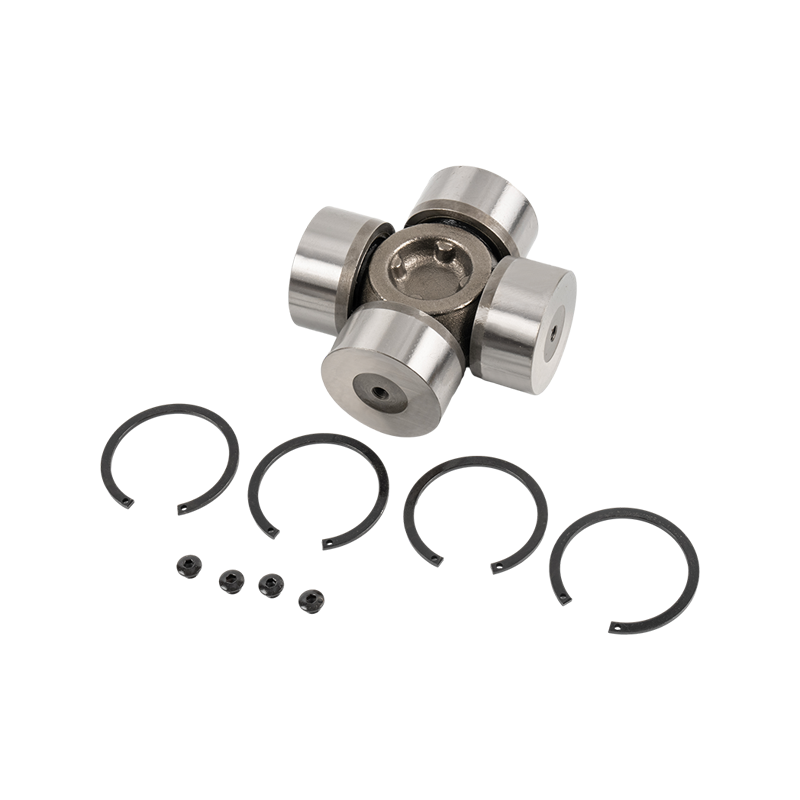

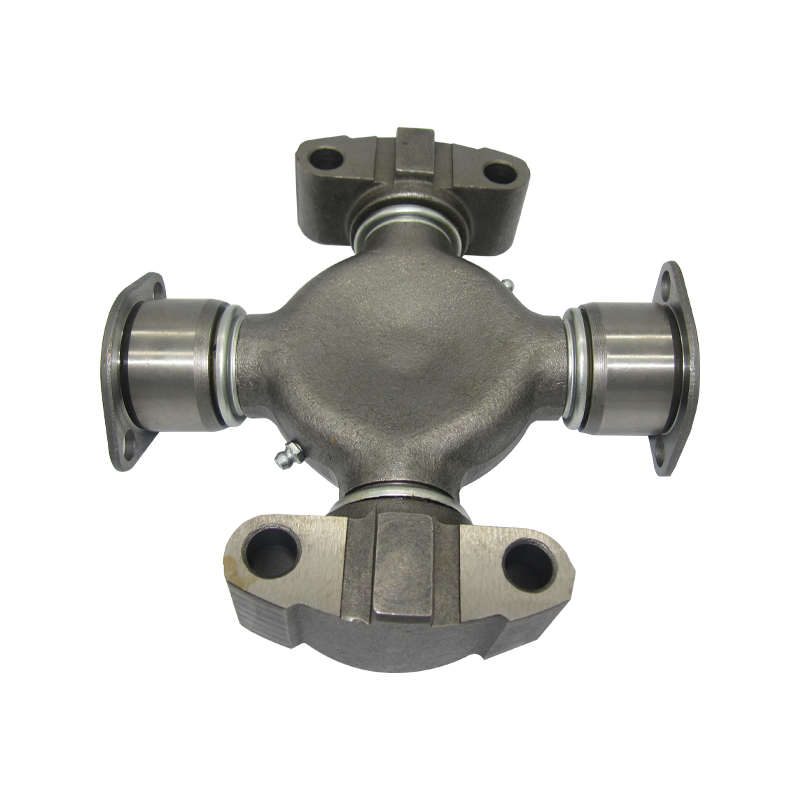

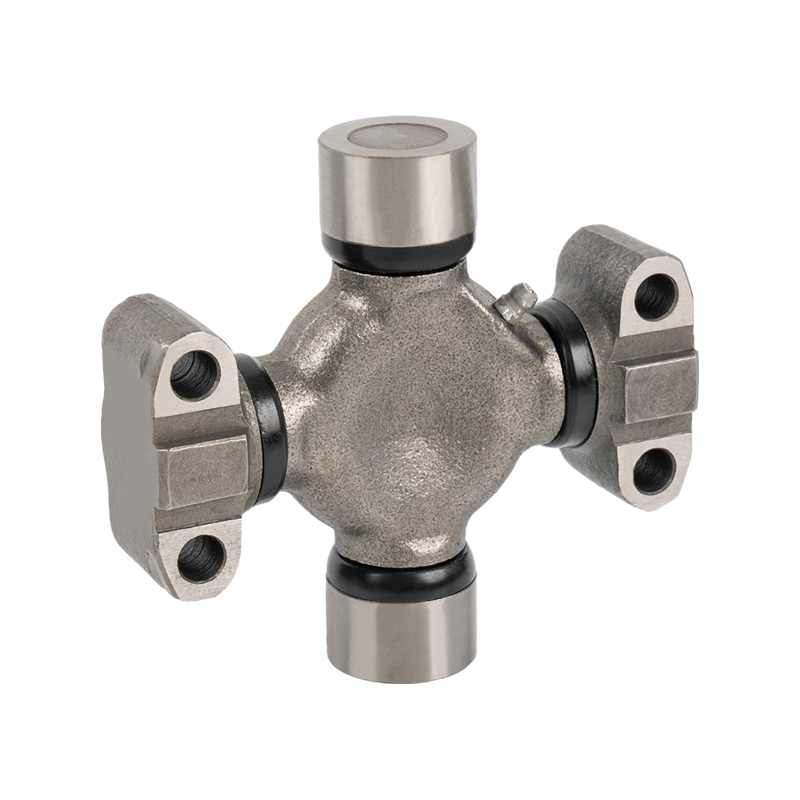

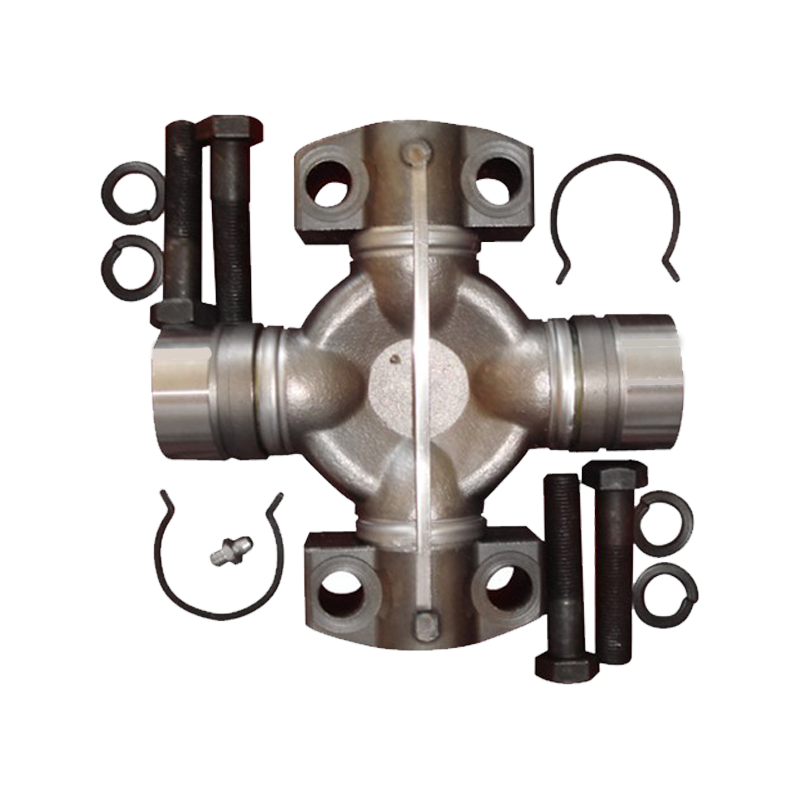

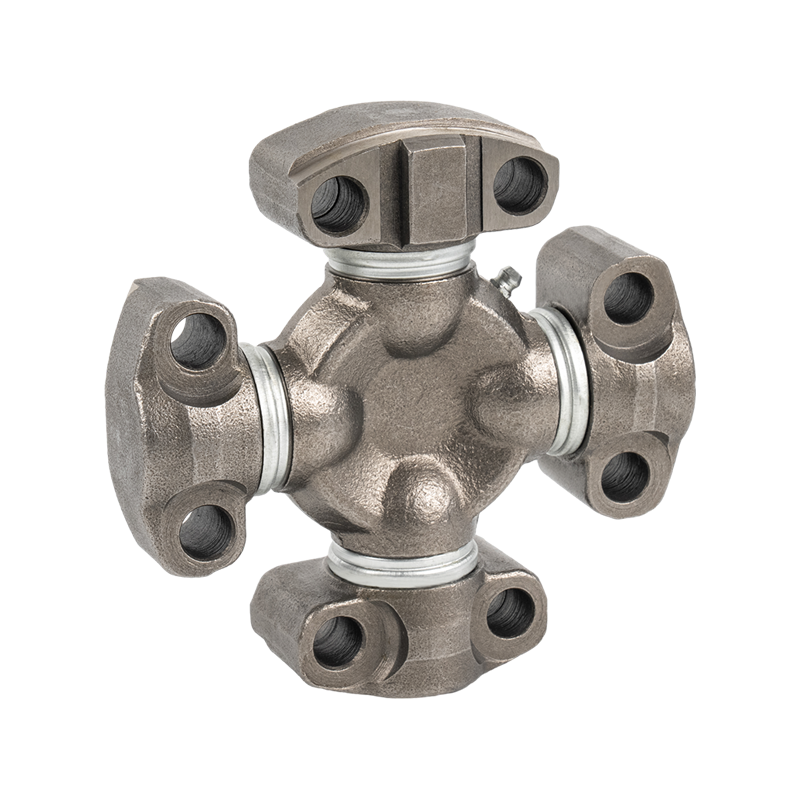

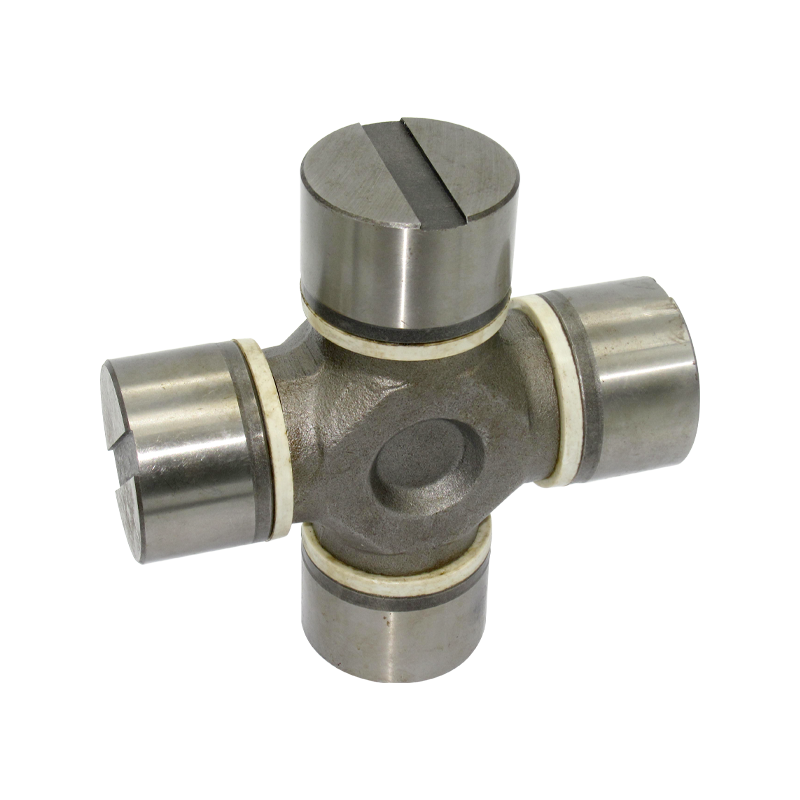

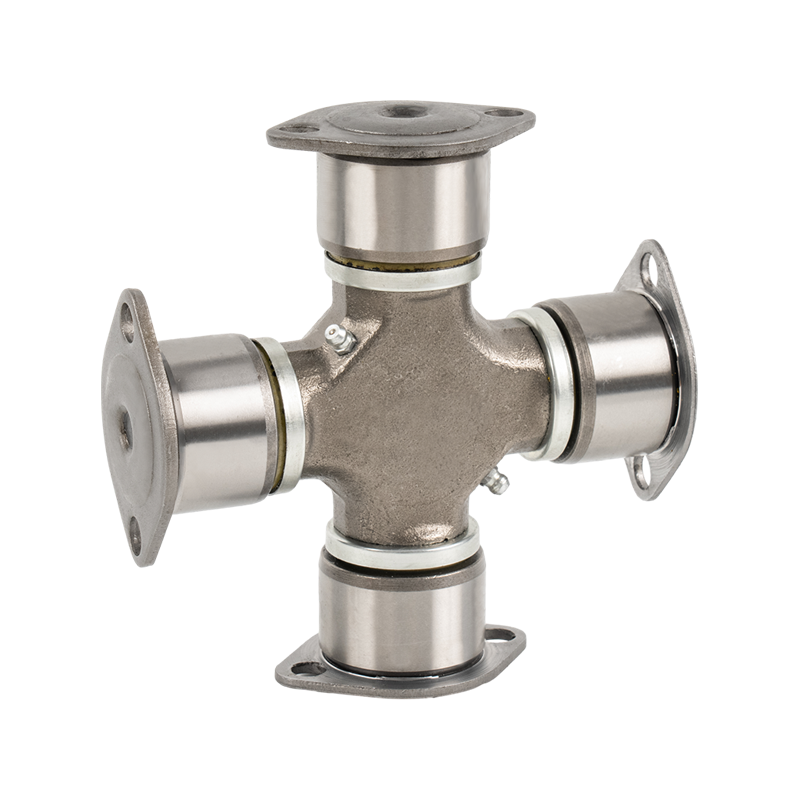

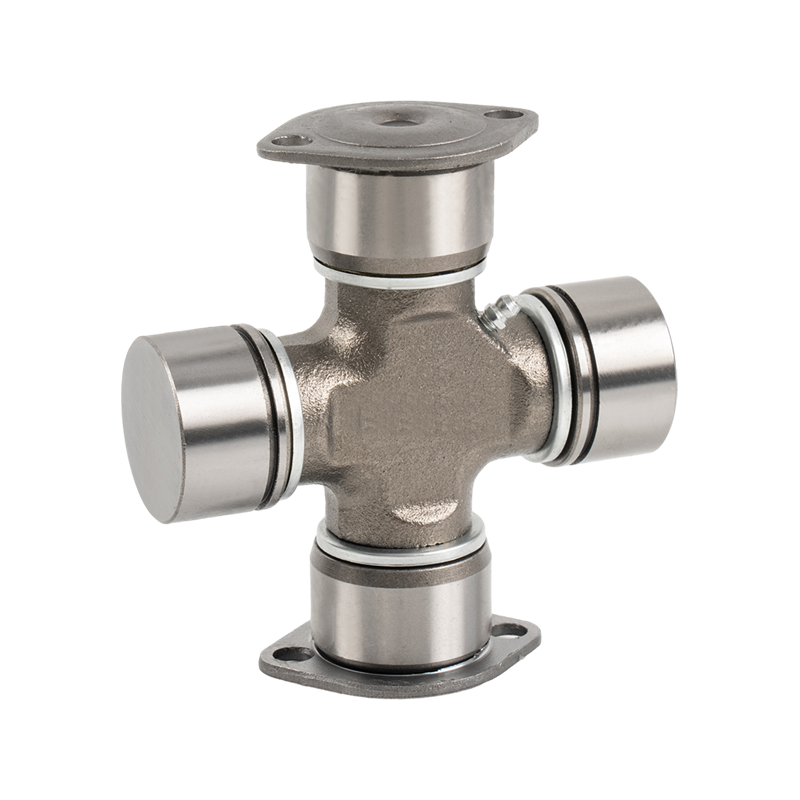

As an important component in automobile transmission system, U-Joint with 4 Grooved Bearings plays a key role. It not only connects and transmits driving force, but also needs to adapt to various working conditions and challenges.

In automobiles, U-Joint with 4 Grooved Bearings are usually installed in key positions of the transmission shaft, such as between the drive shaft and the transmission shaft, to connect and transmit torque. One of its main functions is to allow the shaft to work under misaligned angles, such as the angle change between the transmission shaft and the differential, or the different angles of the wheel axle during steering. This design allows the car to maintain the stability and efficiency of the transmission system during cornering and suspension movement.

One of the advantages is its ability to maintain stability and reliability under high torque and high-speed operation conditions. The design of the grooved bearing effectively improves the transmission efficiency and load-bearing capacity of the shaft, and reduces the noise and vibration caused by vibration and imbalance in the transmission. This is crucial to improving driving comfort and ensuring the reliability of long-term operation of the vehicle.

In addition, the durability and long life of U-Joint with 4 Grooved Bearings are also its significant advantages in automotive transmission systems. Because it is made of high-strength and wear-resistant materials, this universal joint can withstand long-term high-frequency use and complex environments, and is not prone to wear or failure. This feature reduces the frequency of vehicle maintenance and replacement of parts, reducing the overall cost of vehicle operation.

In practical applications, U-Joint with 4 Grooved Bearings often needs to consider its coordination and integration with other transmission system components, such as bearings, bearing seats and lubrication systems. This requires strict engineering standards and testing during the design and manufacturing process to ensure the coordination and interaction between the various components, thereby improving the efficiency and reliability of the overall system.

English

English 中文简体

中文简体