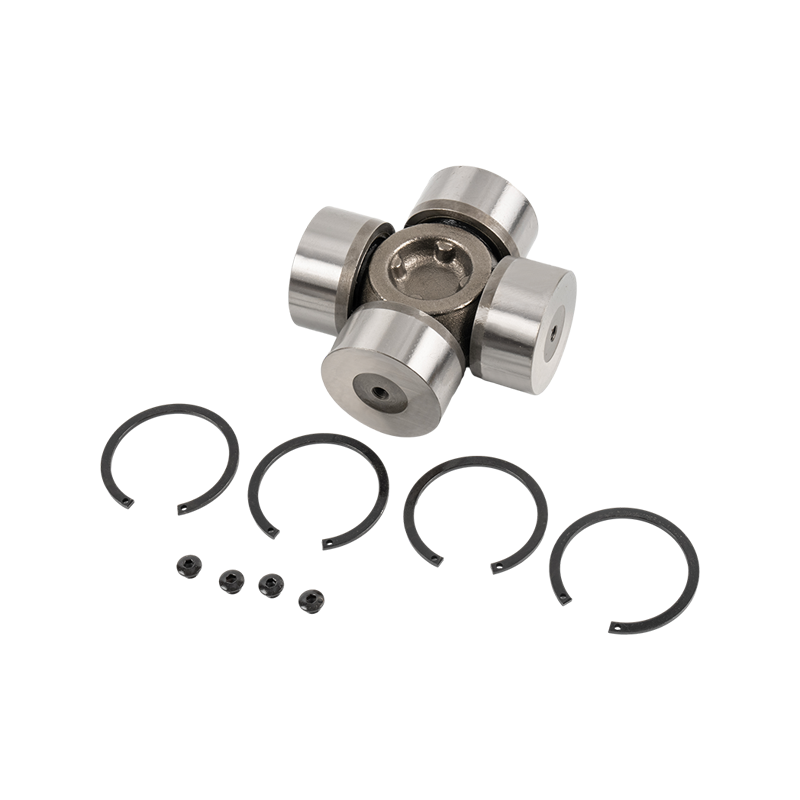

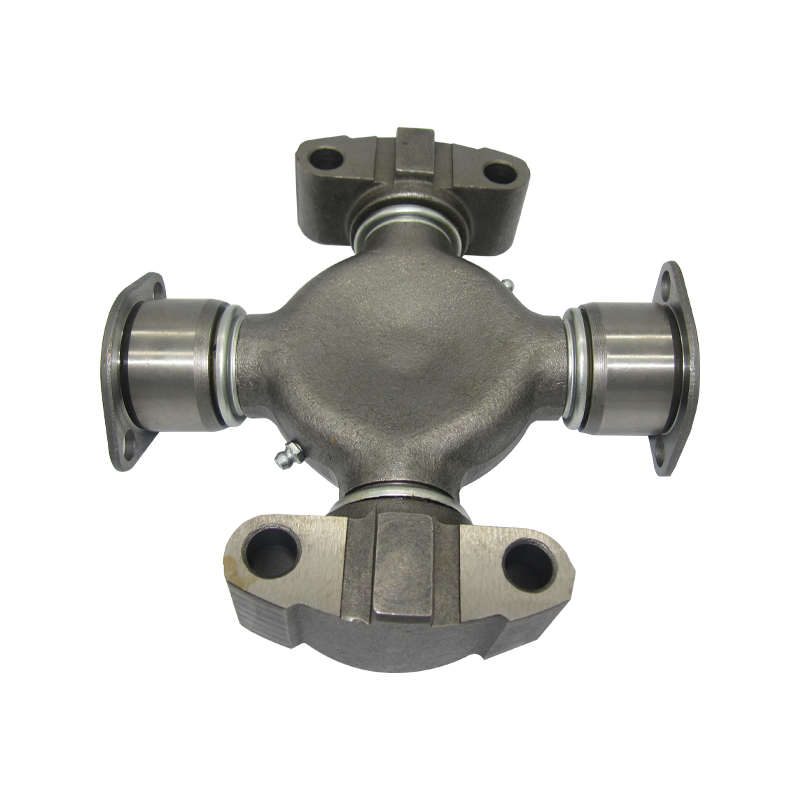

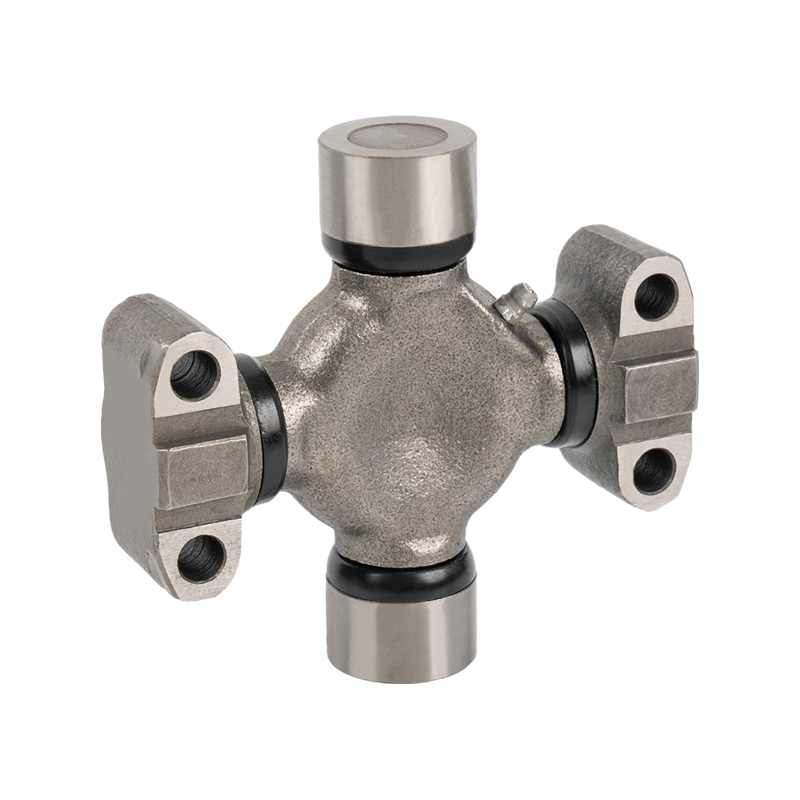

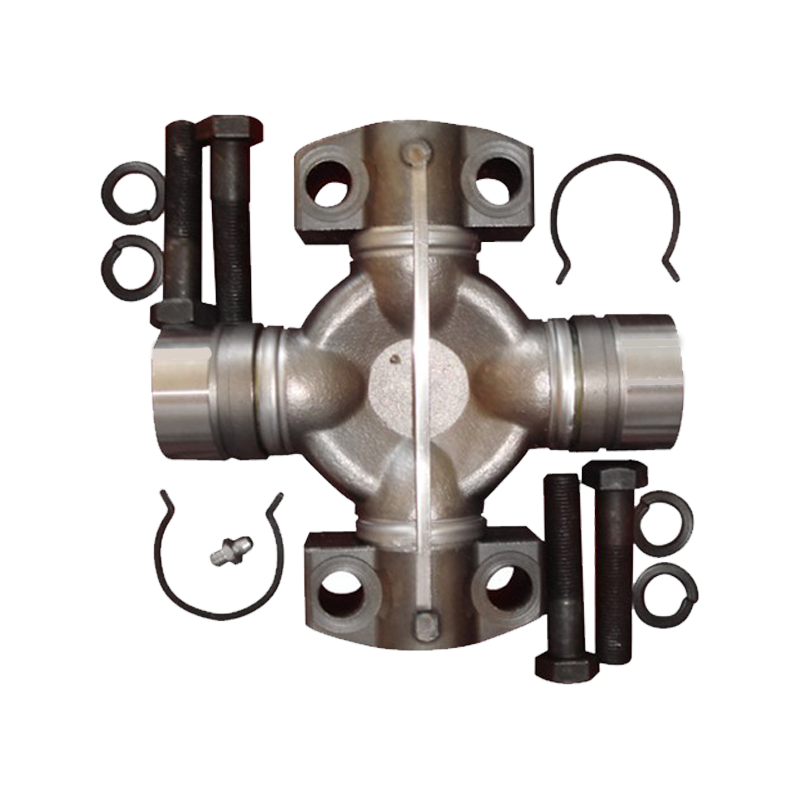

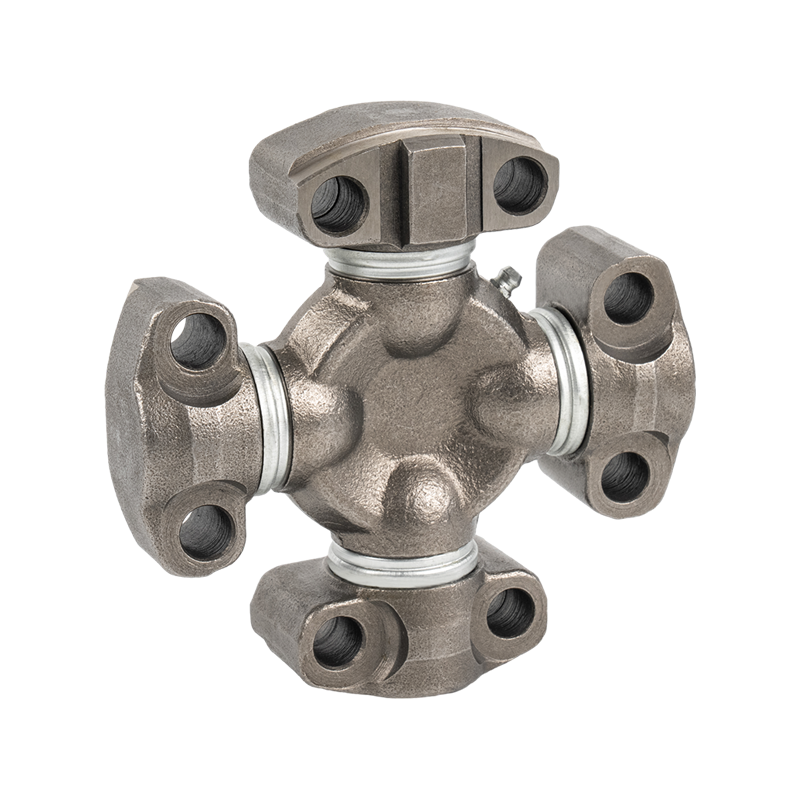

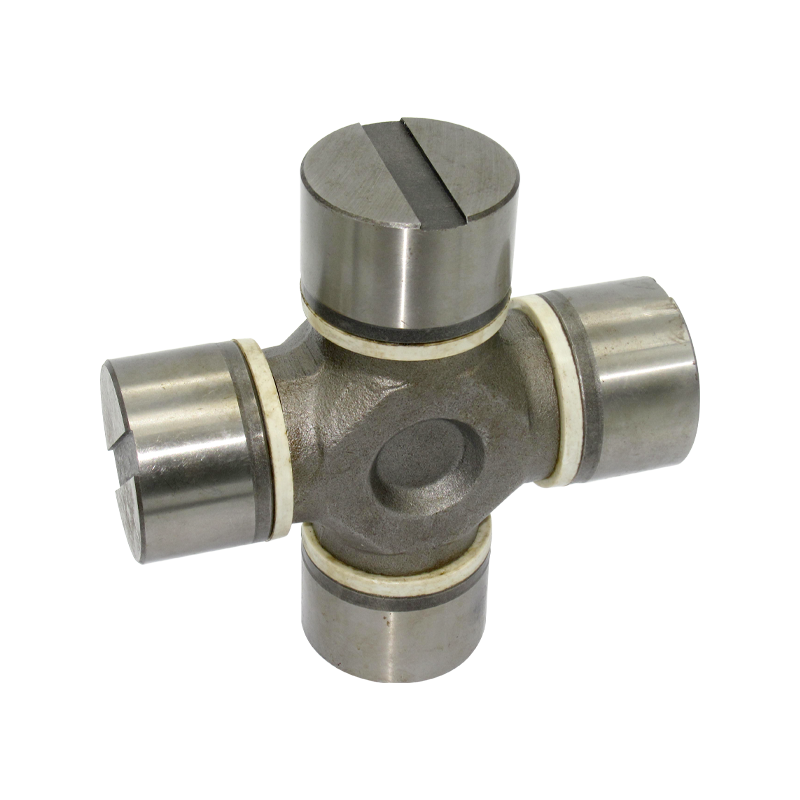

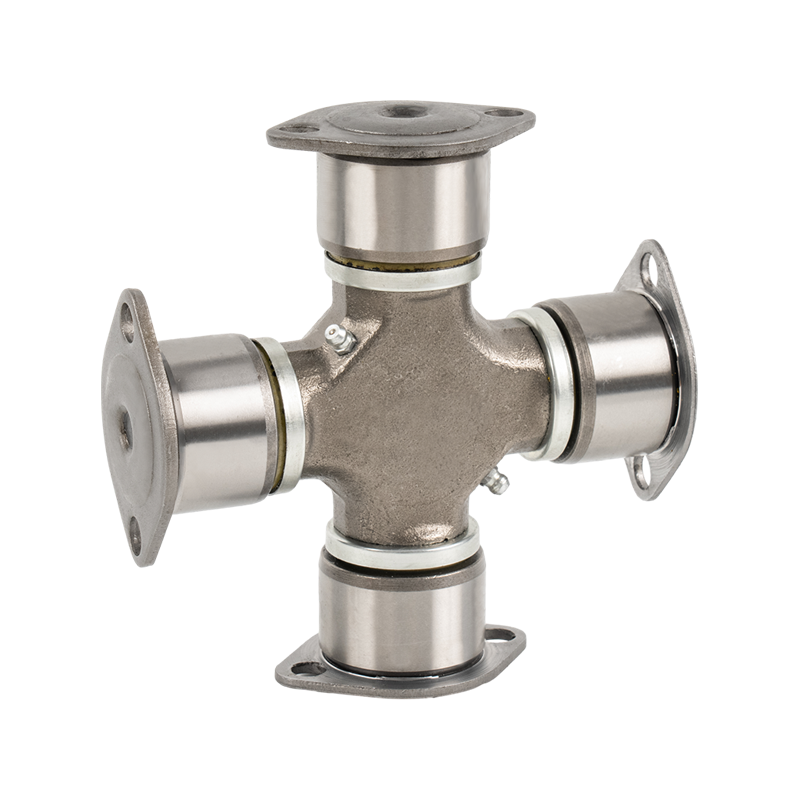

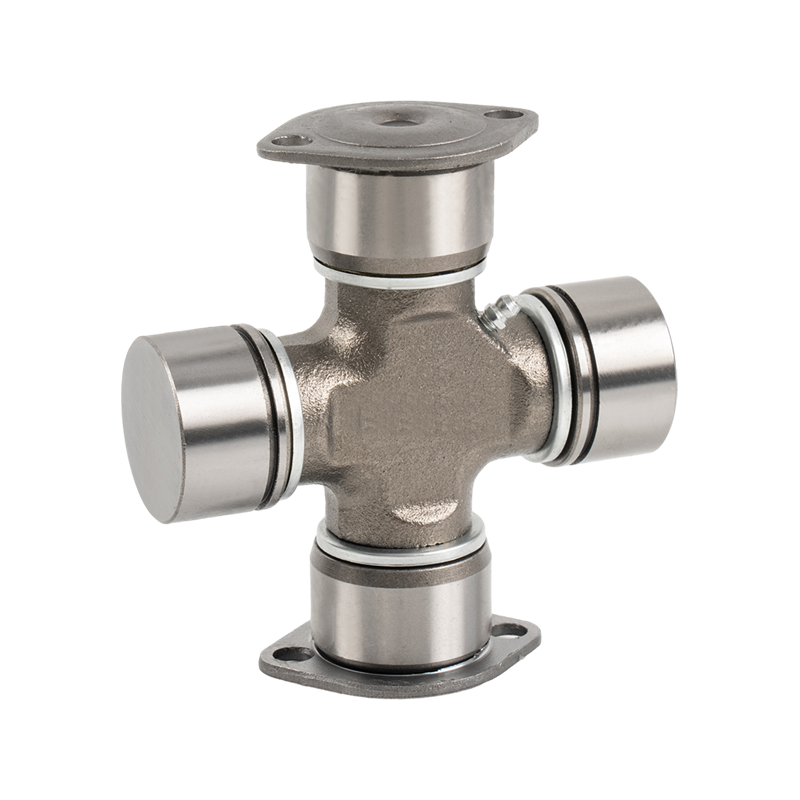

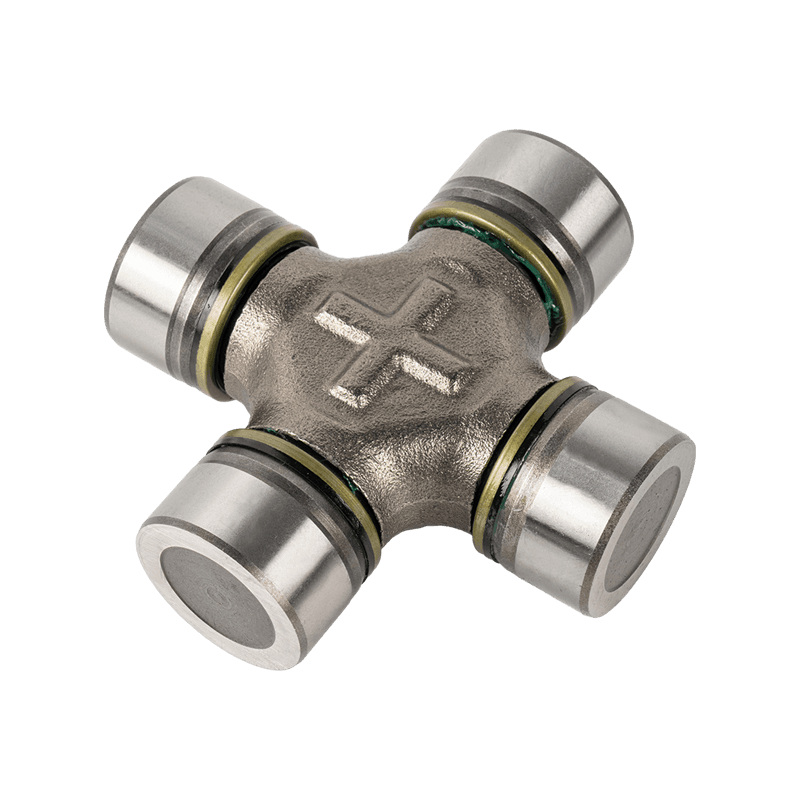

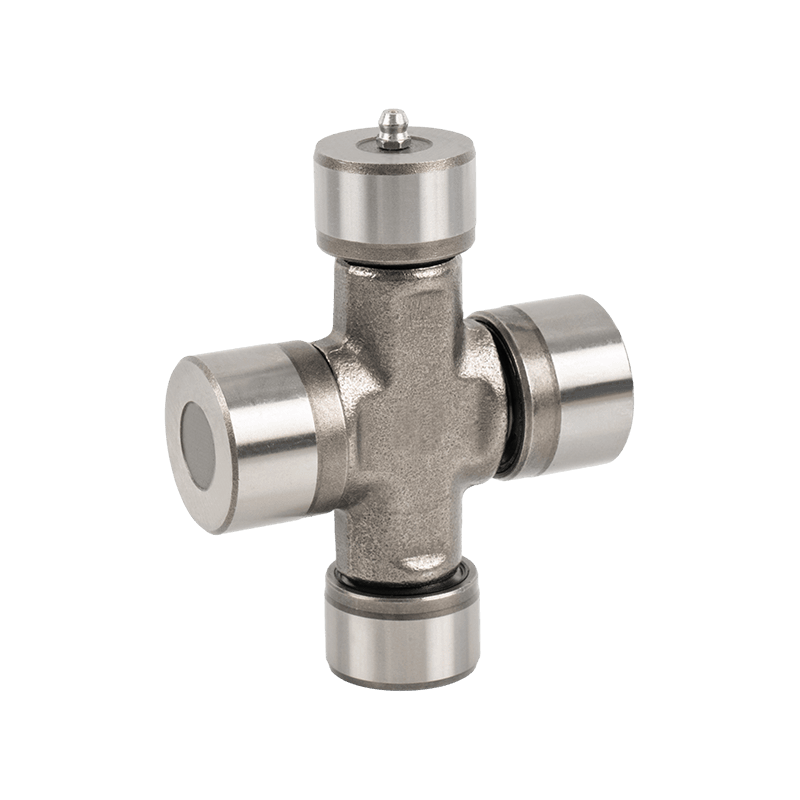

Optimized design of U-JOINT WITH 4 PLAIN ROUND BEARINGS products

One of the core optimizations of the U-JOINT WITH 4 PLAIN ROUND BEARINGS is the use of four bearings to maximize load distribution efficiency. Each bearing is precisely arranged at different parts of the universal joint to evenly share the axial and radial loads during the transmission process. With this optimization, the universal joint can maintain a low friction coefficient and temperature rise at high speeds, ensuring efficient power transmission. Universal joints of different sizes (such as WGAX1, D=23.820mm, L=61.30mm and WGAX7, D=30.180mm, L=92.08mm) show adaptability under different load requirements, and the bearing size and number are adjusted accordingly to maintain excellent stability under greater loads. For high-load applications (such as WGAX7), the four-bearing design effectively avoids excessive wear of a single bearing, while improving impact and seismic resistance, allowing the universal joint to operate stably for a long time in a more demanding working environment. Compared with traditional two-bearing or three-bearing designs, this optimization significantly improves the overall durability of the product, especially under complex dynamic load conditions.

The precision machining of U-Joint With 4 PLAIN ROUND BEARINGS is another highlight of its optimized design. All dimensions of the product are manufactured strictly in accordance with the design standards to ensure that the precise matching requirements can be achieved during assembly and operation. Taking WGAX2 (D=27.000mm, L=74.60mm) as an example, the product accurately controls every key parameter during the production process, so that the universal joint will hardly vibrate or be unstable when rotating. Precision machining can effectively prevent unbalanced operation caused by assembly errors or improper dimensions, thereby extending the service life of the product. In addition, U-Joint products are also strictly controlled to ensure the matching accuracy of bearings and bearing seats. This high-precision design enables the universal joint to maintain good stability during long-term operation, especially at high speeds, which can minimize the additional stress and wear caused by uneven loads or poor matching.

In order to adapt to harsh working environments, U-JOINT WITH 4 PLAIN ROUND BEARINGS uses high-quality alloy steel materials such as GU400, GU1100, GU2200, etc. These materials have significant advantages in strength, hardness and wear resistance. For example, GU400 (commonly used in WGAX1 model) is an alloy steel with high wear resistance and tensile strength, suitable for high load and frequent impact working occasions; while GU2200 (used in WGAX7) is more suitable for applications in high temperature and harsh environments, and can withstand higher mechanical stress and temperature fluctuations. The selection of these materials enables U-Joint to perform well not only under normal working conditions, but also to work stably for a long time in extreme environments. For example, in agricultural machinery, heavy trucks and construction machinery, the wear resistance and corrosion resistance of the universal joint can significantly reduce the frequency of maintenance and replacement, and reduce operating costs.

In addition to high-strength alloy steel materials, U-JOINT WITH 4 PLAIN ROUND BEARINGS also uses sophisticated heat treatment processes (such as quenching and tempering) to further improve its hardness and wear resistance. This heat treatment technology enables the universal joint to maintain stable performance under high temperature and high load environments, especially in internal combustion engines and heavy industrial equipment, which can effectively reduce the problems caused by thermal expansion. In addition, surface treatment technology is also an important part of the optimized design of universal joints. Through processes such as surface chrome plating and spraying, the corrosion resistance of the product can be improved to prevent the erosion of the product by external environments such as salt spray and chemicals. This is especially important for equipment operating in marine environments or hot and humid environments.

The specifications and designs of four-bearing universal joints are very rich, and suitable models can be selected according to different load requirements and space requirements. For example, WGAX4 (D=27.010mm, L=74.60mm) and WGAX6 (D=27.000mm, L=81.76mm) are designed for medium loads and long working cycles, while WGAX7 (D=30.180mm, L=92.08mm) is customized for heavy-duty applications. The diversity of size and design enables the product to be widely used in multiple industries such as agriculture, automobiles and construction machinery to meet the needs of different working environments.

English

English 中文简体

中文简体