Metal expansion U-joints are mainly used to connect two shafts

The metal extended U-joint is a critical mechanical component that is primarily used to connect two shafts to achieve rotational motion and compensate for axial movement caused by temperature changes or vibrations. The unique design of this joint combines the advantages of a standard U-shaped joint while adding a telescopic function to enhance its adaptability and flexibility.

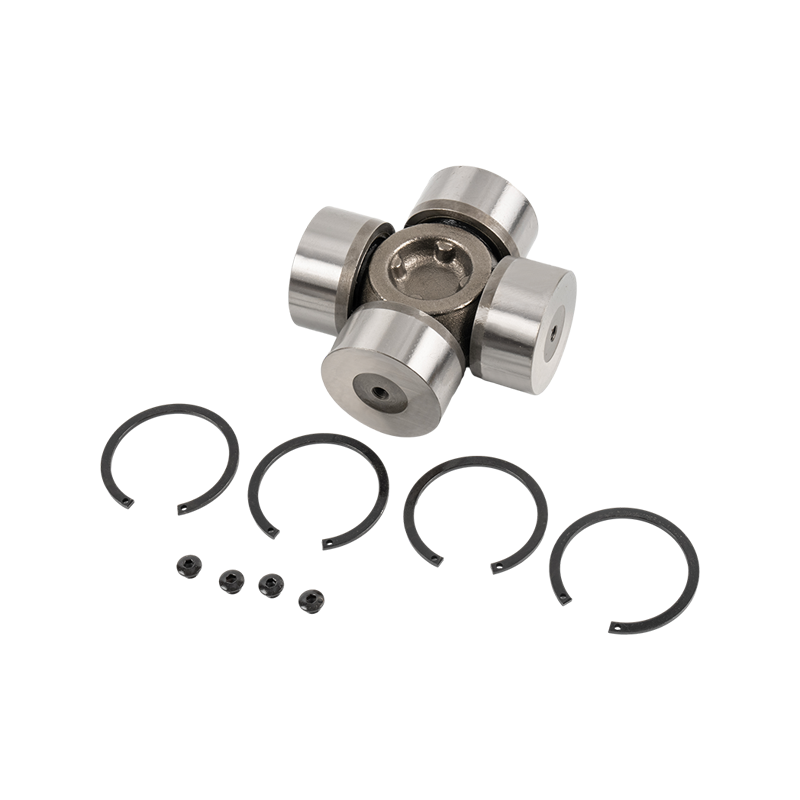

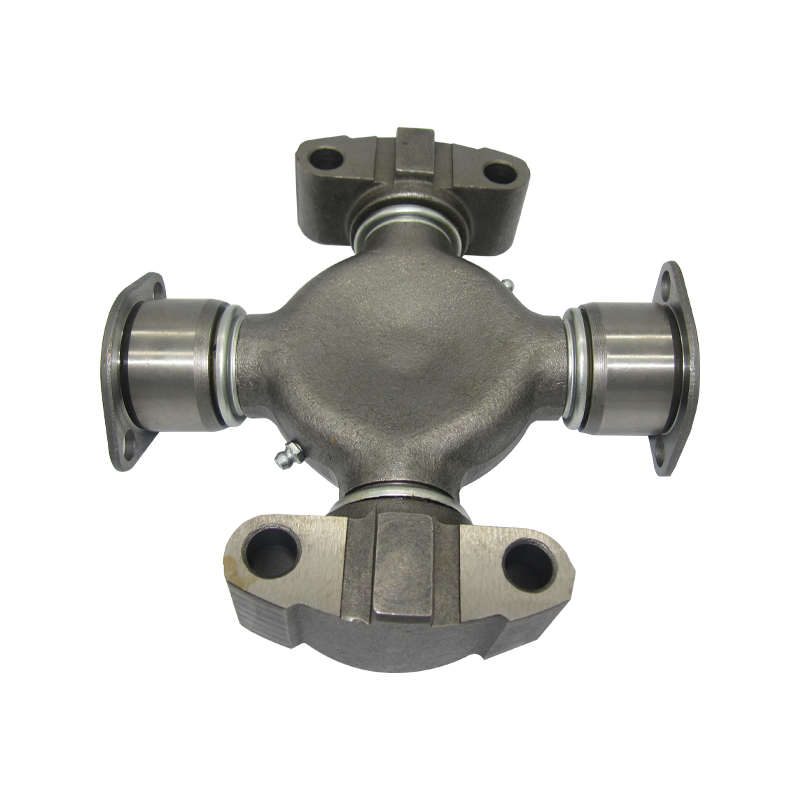

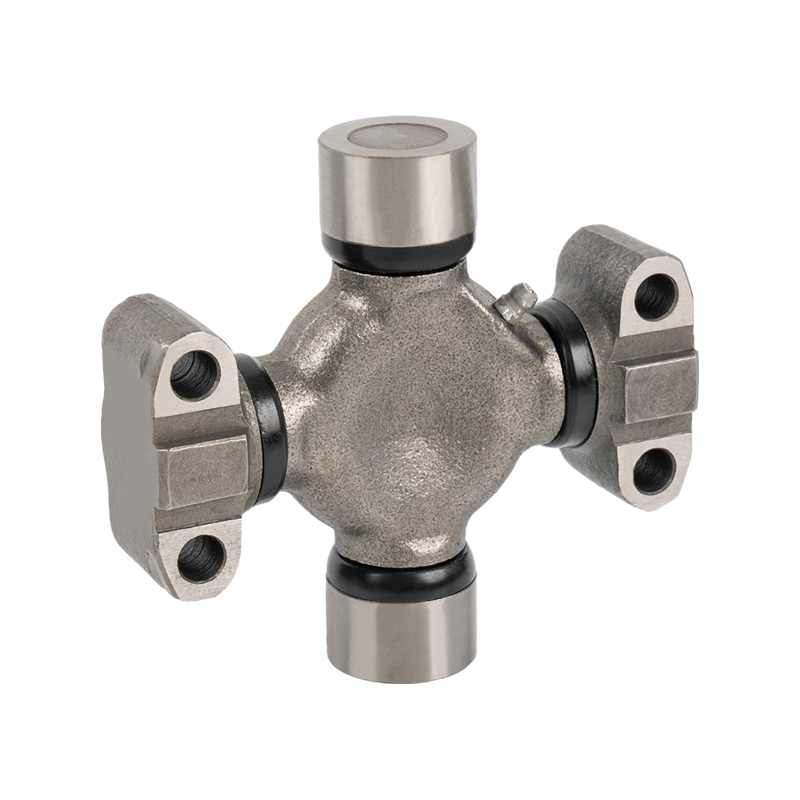

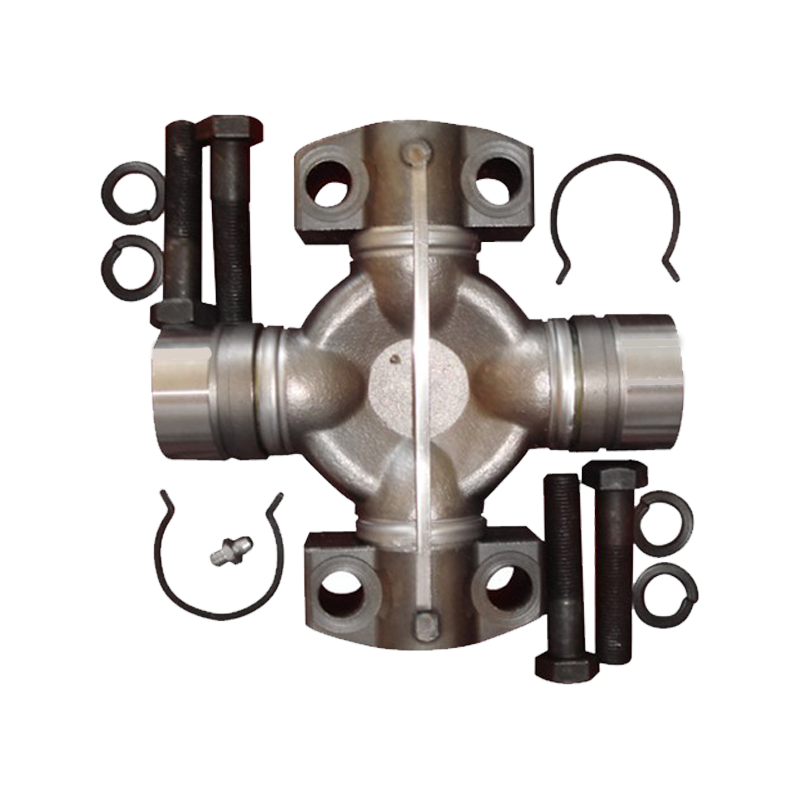

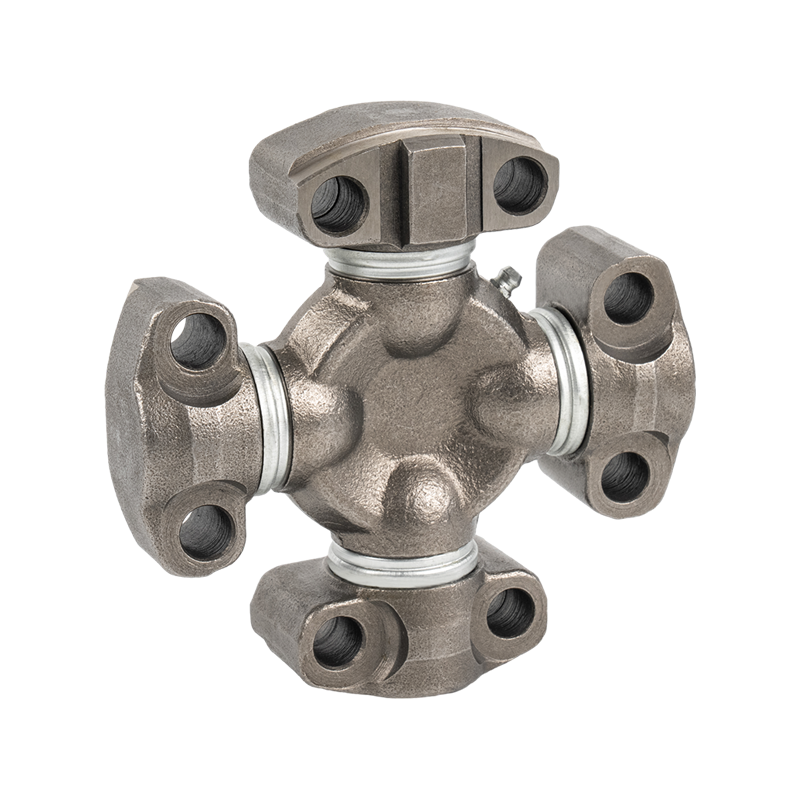

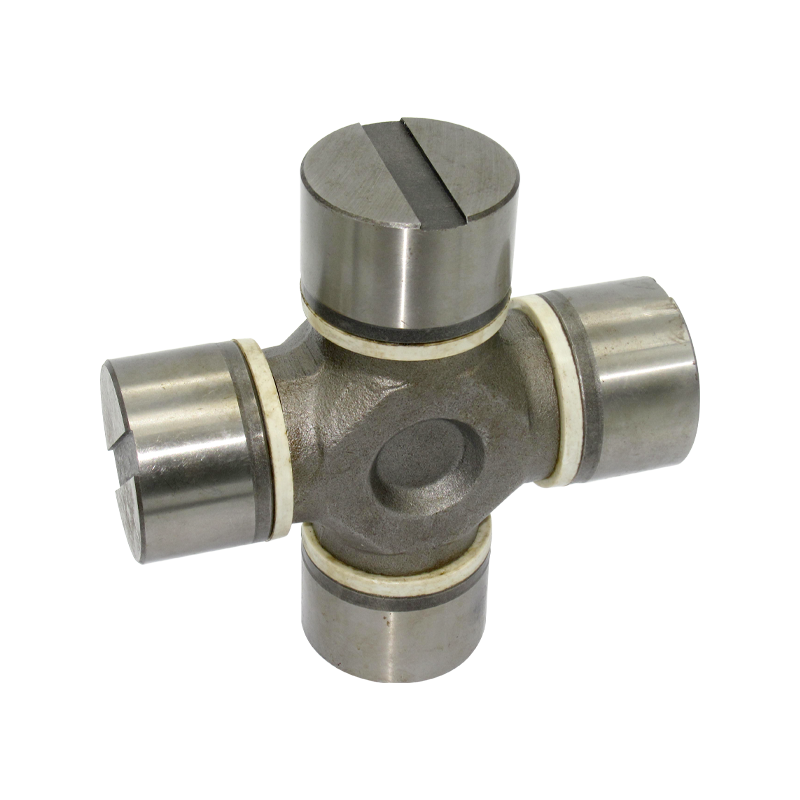

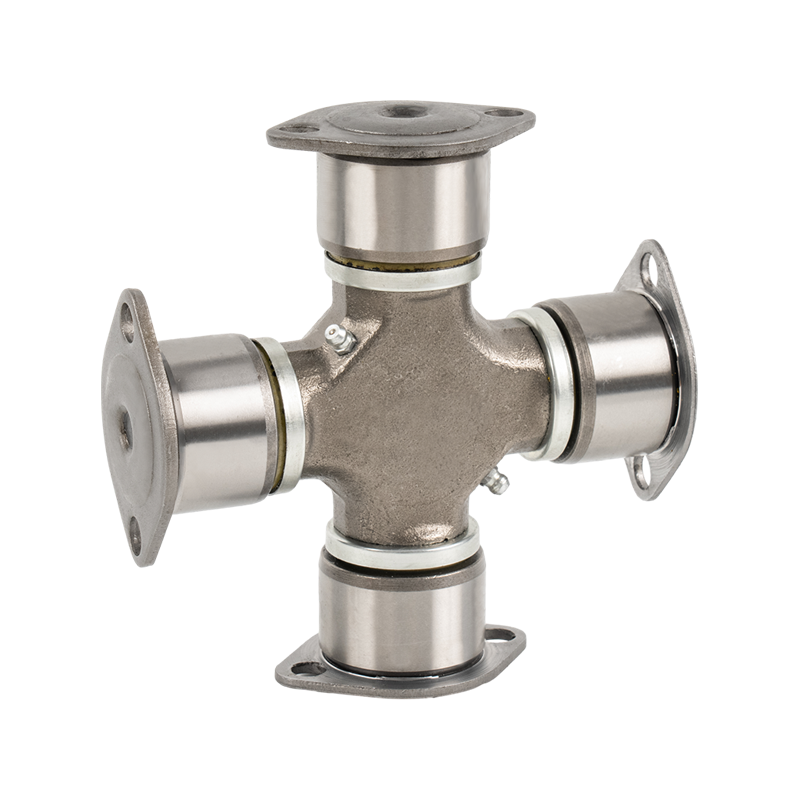

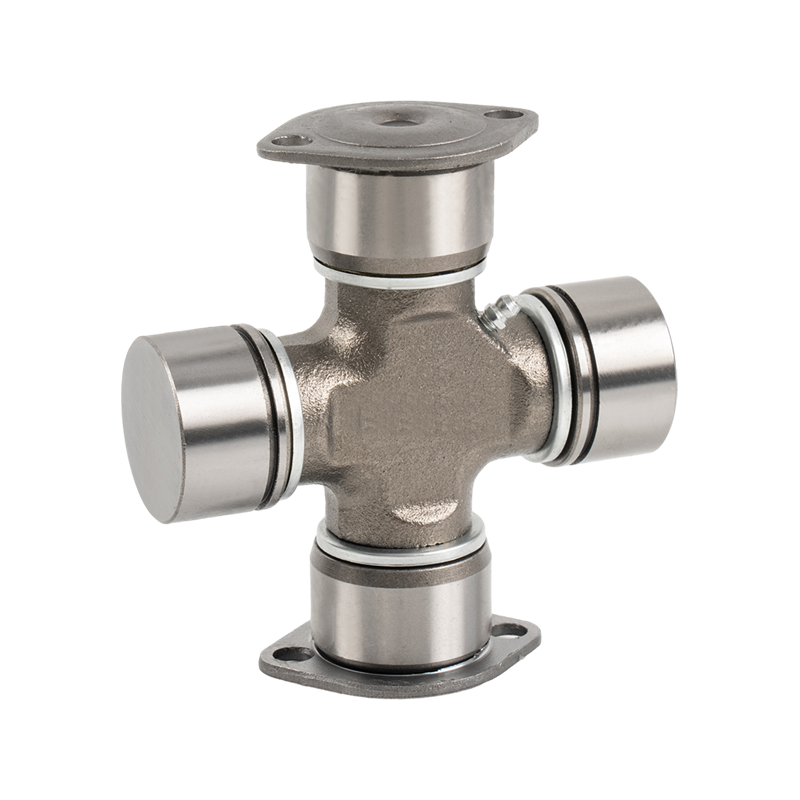

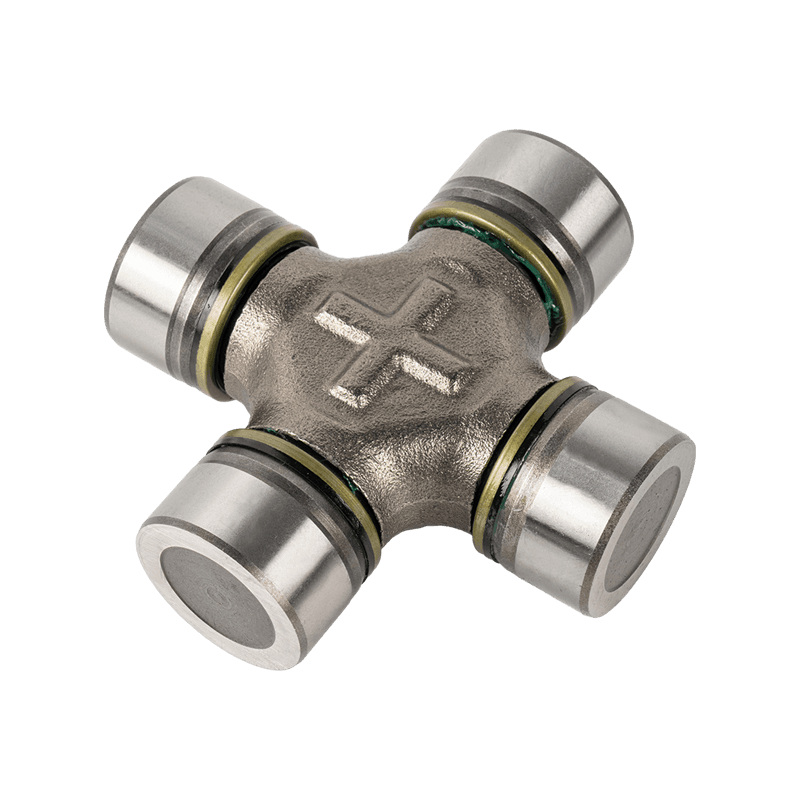

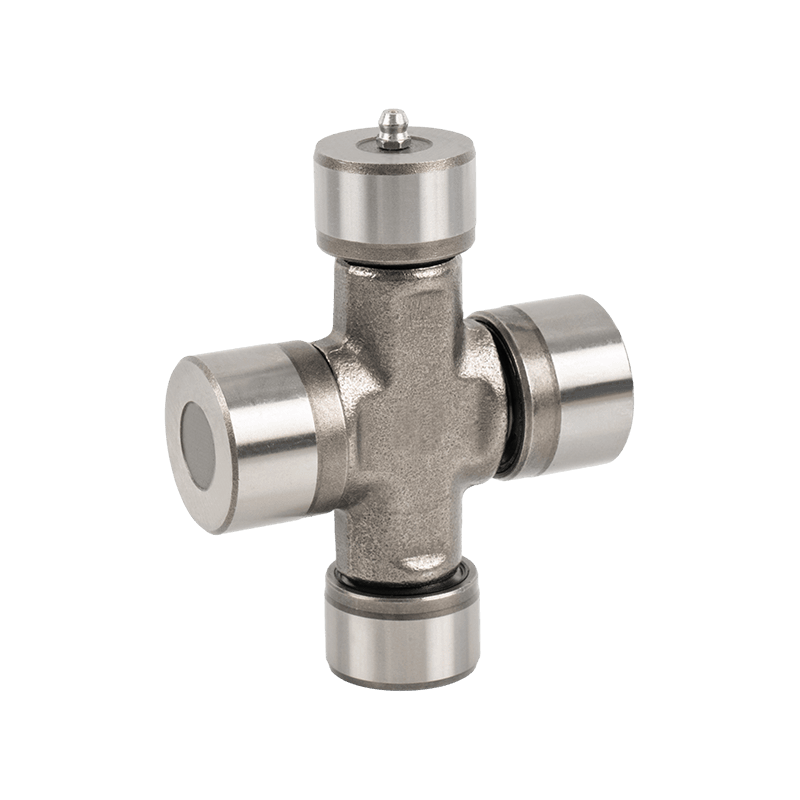

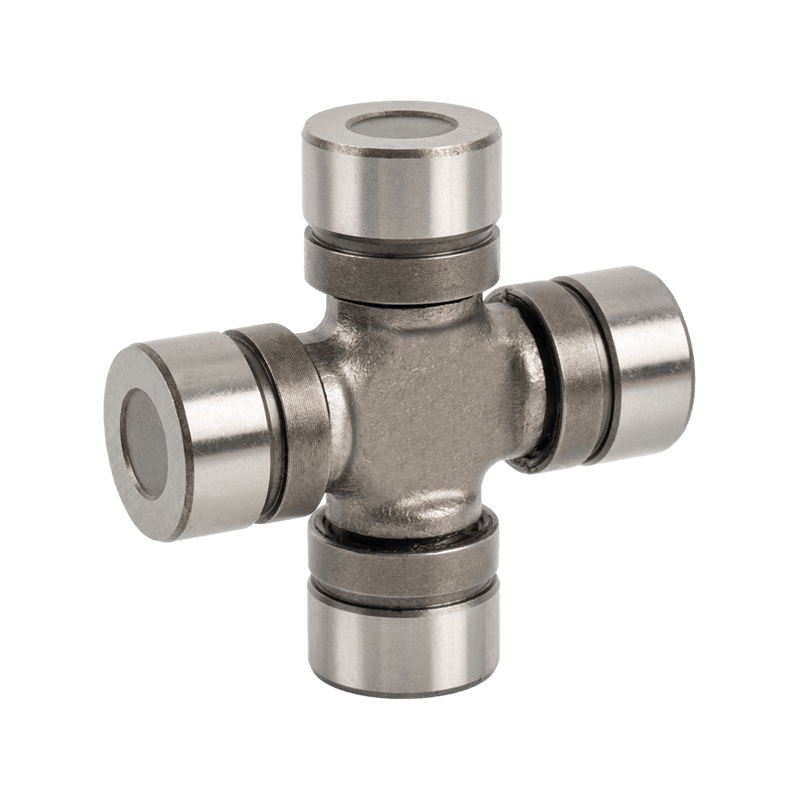

The metal extended U-joint consists of two yokes (trunnions) and a cross-shaped component. The yokes are connected to their respective drive shafts, while the cross-shaped assembly provides the necessary rotational movement. This design allows the connected shafts to move flexibly at different angles, thereby reducing wear on the equipment when transmitting power.

The most notable feature is its telescopic function. The sliding or overlapping mechanism built into the metal expansion U-joint allows it to move axially during operation based on the thermal expansion or contraction of the connecting shaft. This mechanism ensures that in an environment with large temperature changes, the joint can effectively cope with dimensional changes caused by temperature changes, thereby maintaining the stability and safety of the connection.

In terms of application, metal extended U-shaped joints are widely used in automobiles, mechanical engineering, aerospace and other fields. In the automotive industry, it is used to connect the power transmission system to ensure smooth transmission of power. Due to its good adaptability and strong load-bearing capacity, the metal extended U-shaped joint can work reliably in high load and high vibration environments, thereby improving the performance and durability of the entire vehicle.

The metal extended U-shaped joint also has excellent corrosion resistance and wear resistance, which allows it to operate stably for a long time in harsh environments. These features not only extend the life of the equipment, but also reduce the frequency of maintenance and reduce overall operating costs.

English

English 中文简体

中文简体