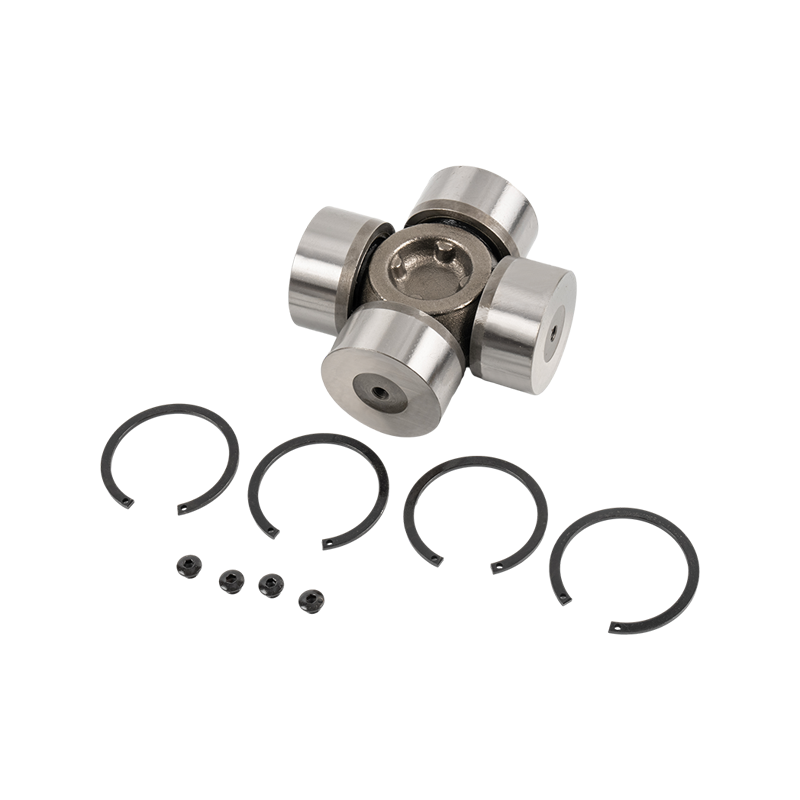

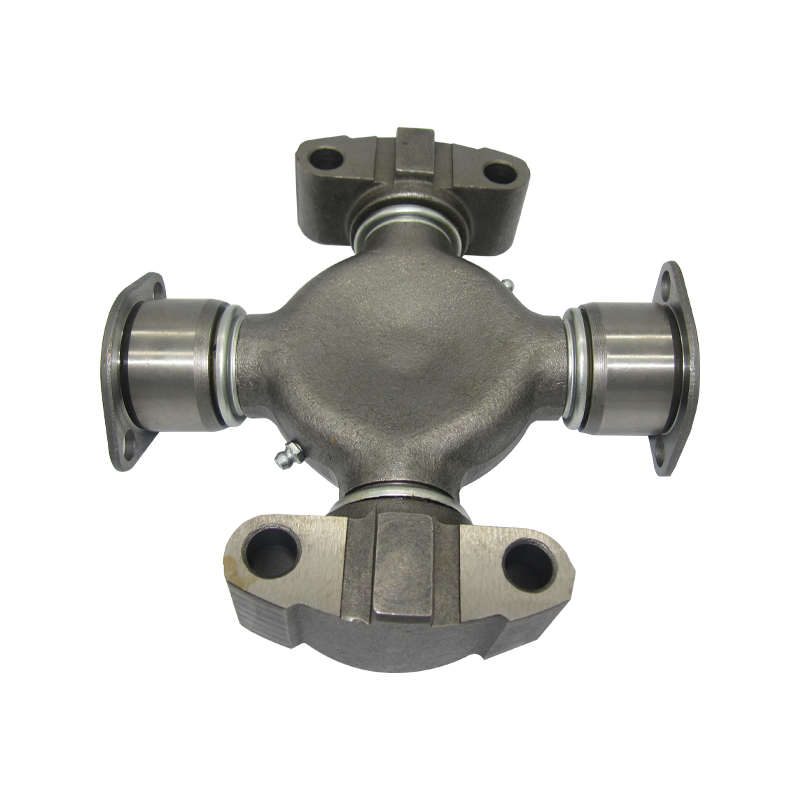

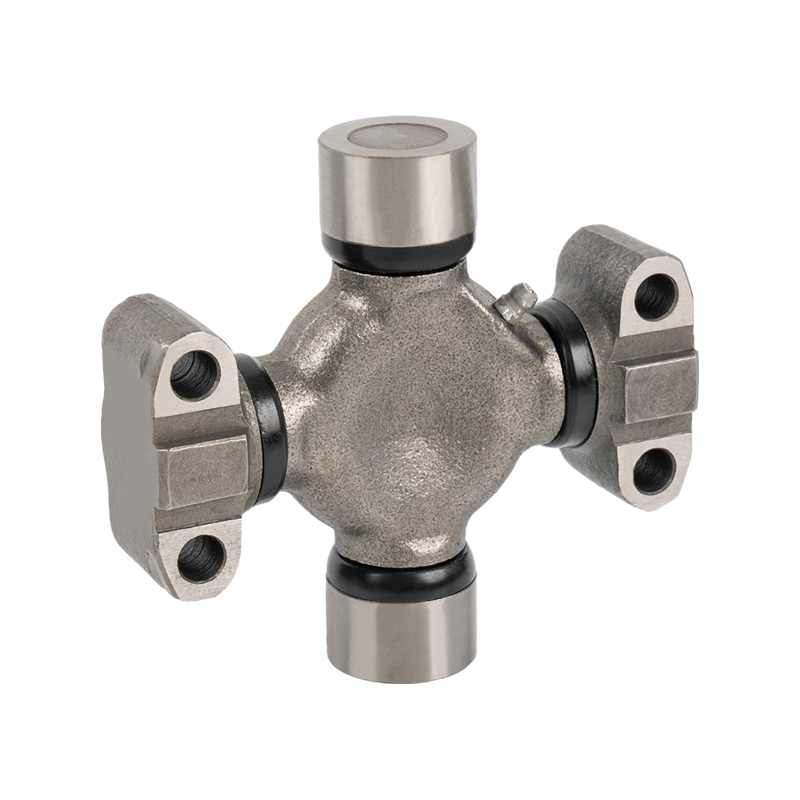

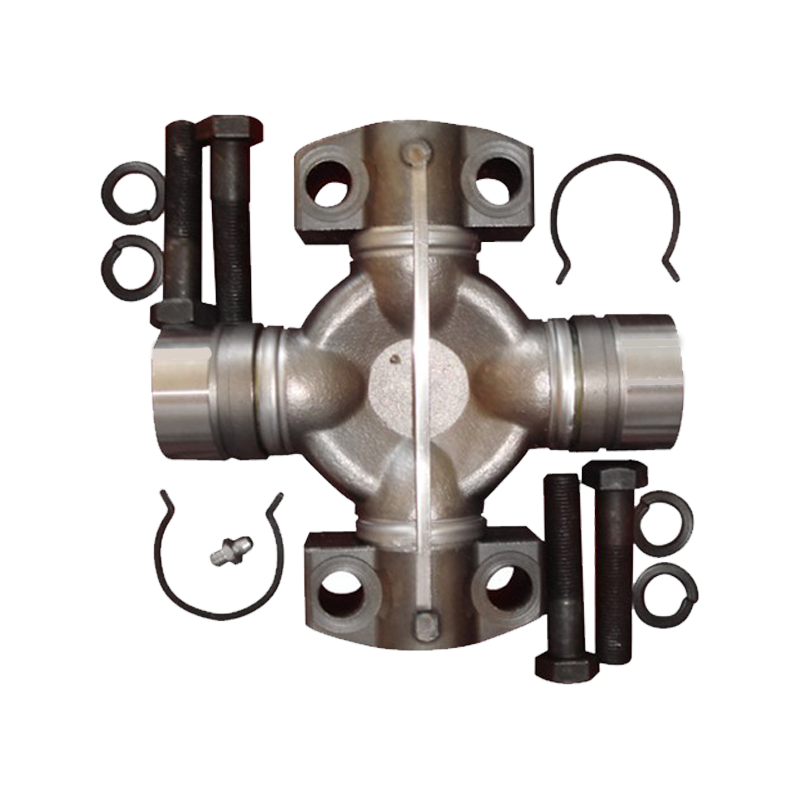

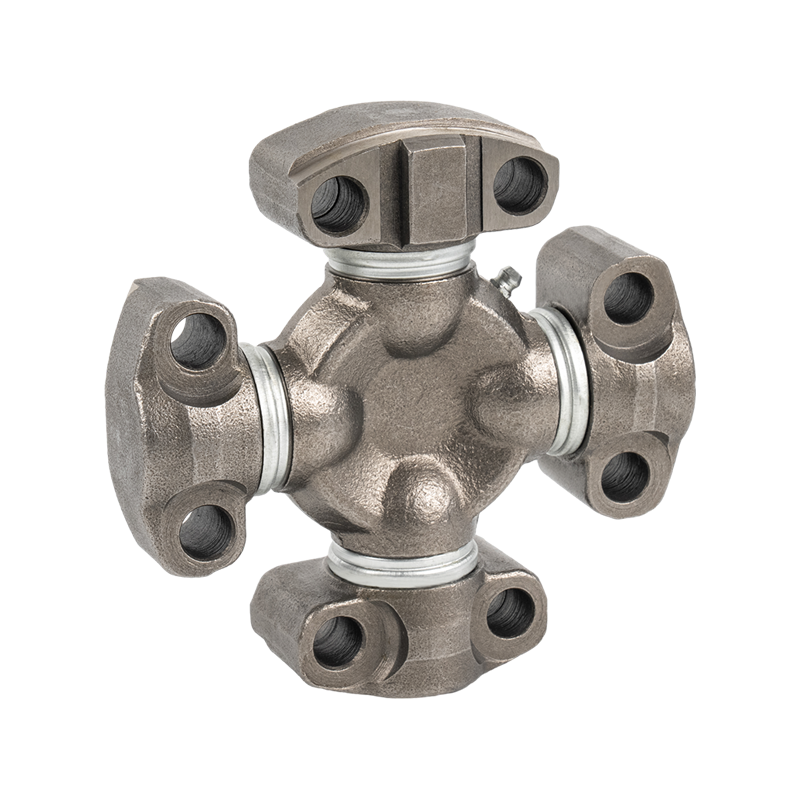

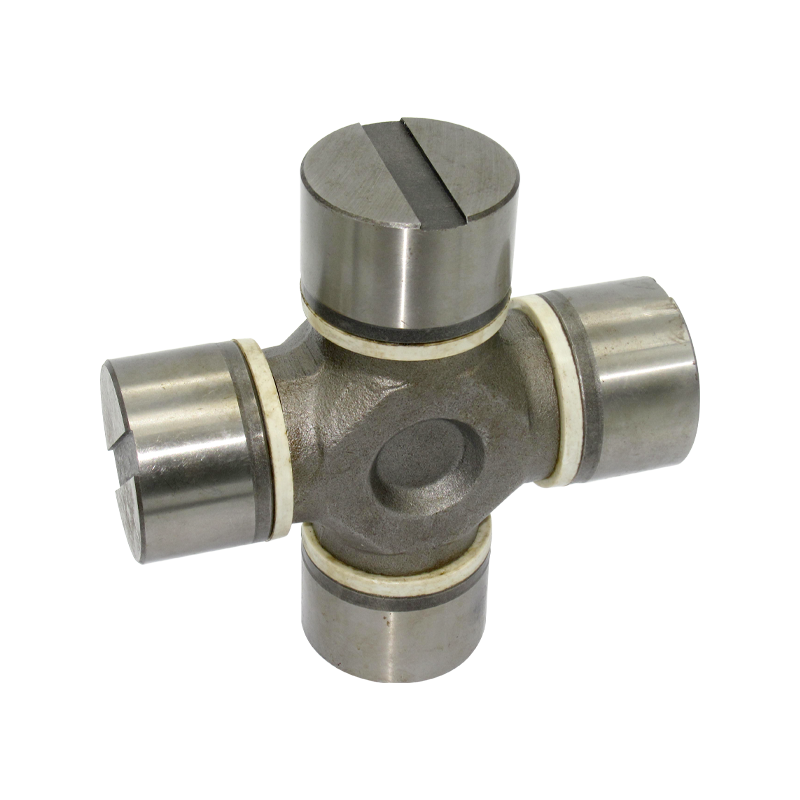

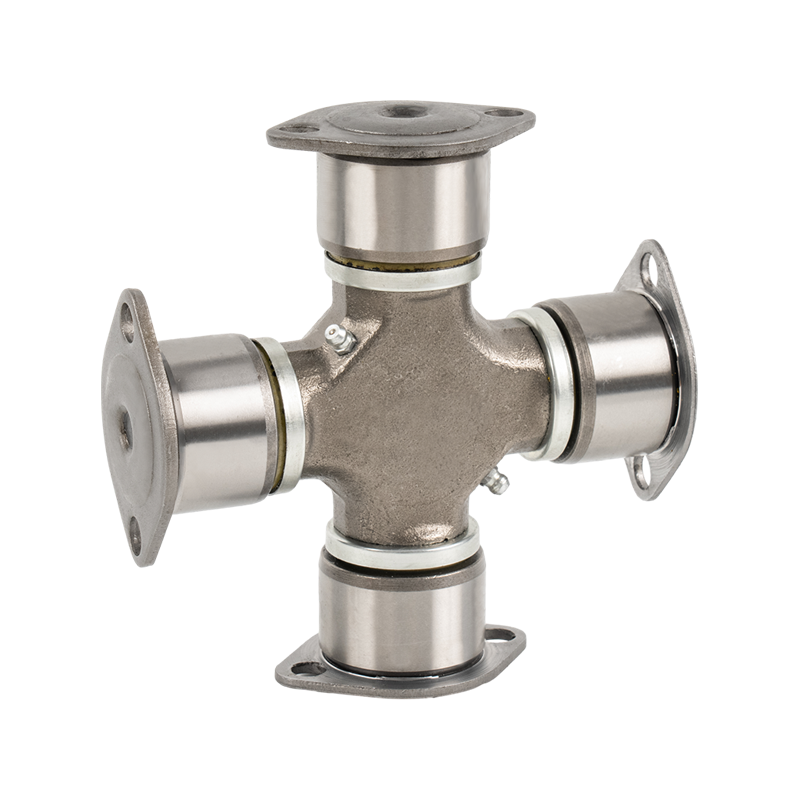

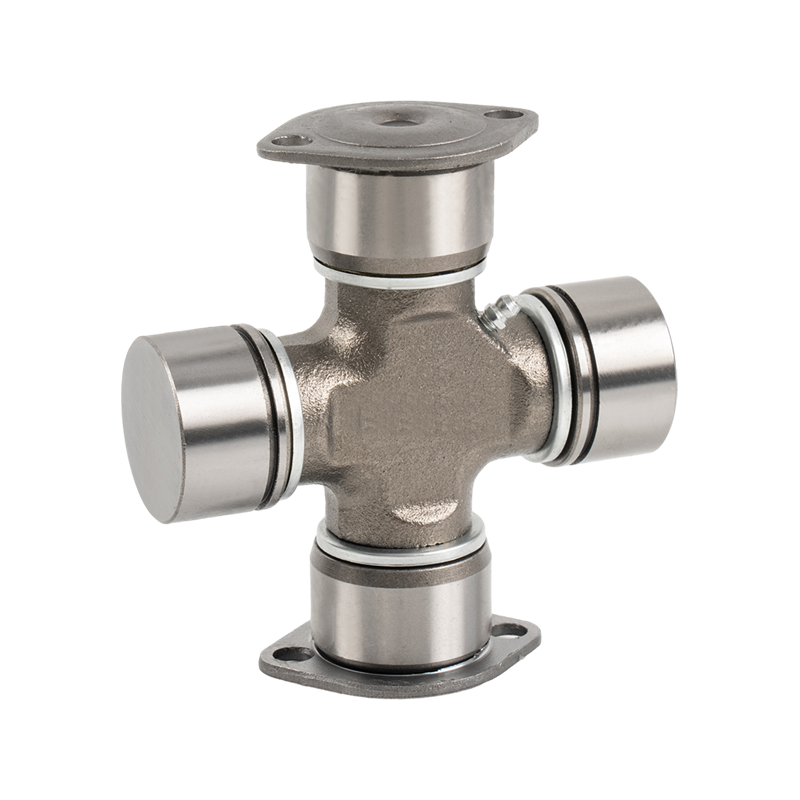

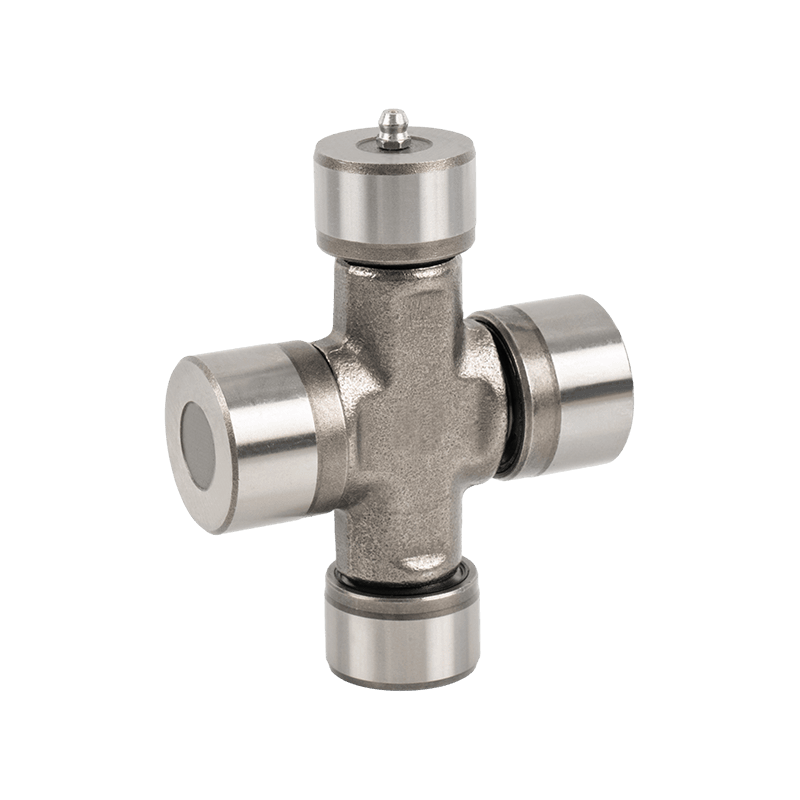

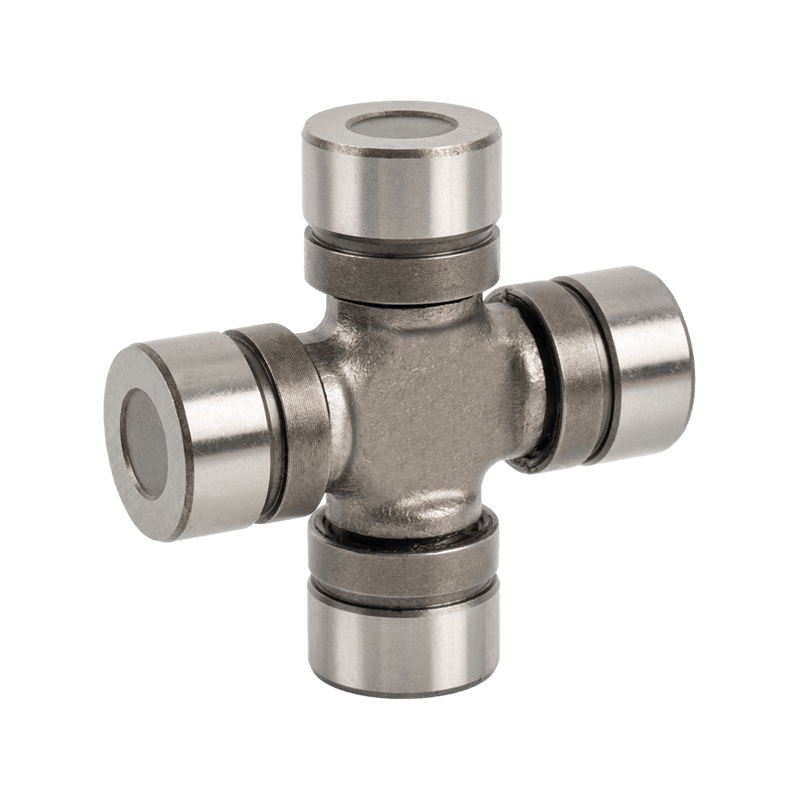

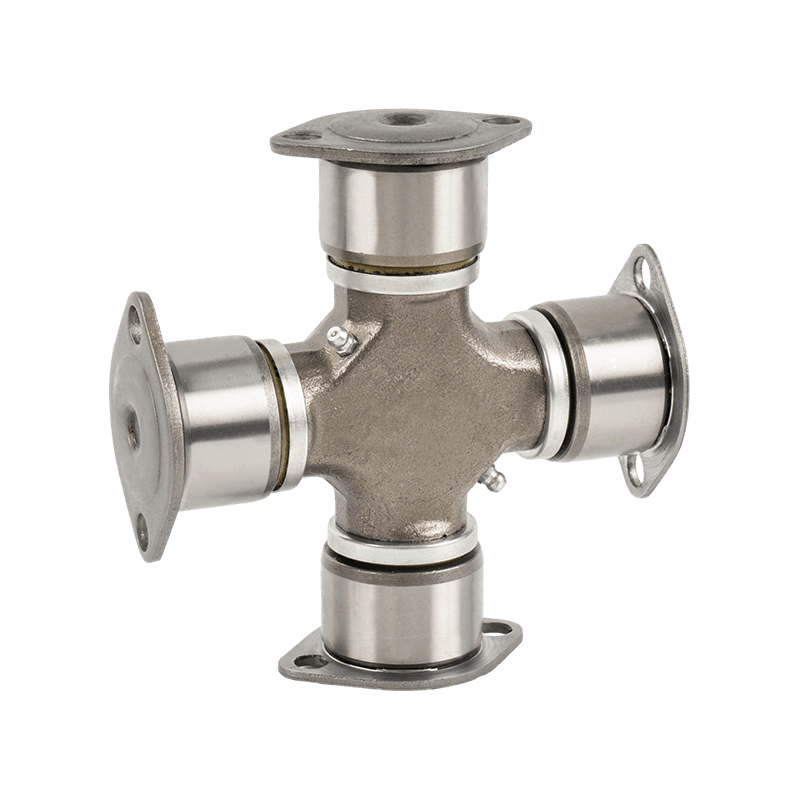

Innovation and Application Prospects of U-JOINT WITH 4 GROOVED BEARINGS in Aerospace Engineering

In aerospace engineering, the high performance and reliability of the transmission system are key factors to ensure flight safety and continuous operation of equipment. As a key component of the transmission system, the design and material selection of U-Joint with 4 Grooved Bearings can meet the requirements of aerospace engineering for lightweight and high strength. Aerospace transmission systems need to achieve maximum power transmission and efficiency in the smallest weight and space, and the use of grooved bearings can effectively reduce the weight of components and improve the overall performance of the system.

U-Joint with 4 Grooved Bearings performs well under high-speed rotation and complex motion conditions. The transmission system in aerospace engineering often needs to work in extreme environments such as high-speed rotation, vibration and deformation, and this optimized design helps to reduce energy loss and wear, ensuring the stability and reliability of the transmission system.

In addition, the design of the grooved bearing improves the torque transmission efficiency of the universal joint while reducing friction loss during movement. This is essential for maintaining performance under long-term operation and extreme temperature conditions in aerospace engineering.

U-Joint with 4 Grooved Bearings is designed for low maintenance and high reliability, and can maintain stable performance in the long-term use of aerospace equipment. Although the maintenance and replacement costs of aerospace equipment are extremely high, this optimized design helps reduce equipment downtime and repair frequency, thereby reducing overall operating costs.

English

English 中文简体

中文简体